The Project: Deploy an Innovative Robotic Welding System

In the rapidly evolving world of advanced manufacturing, the integration of cutting-edge technology is crucial for staying competitive in a global landscape. Smoker Craft Inc., an established boat manufacturer, and Guide Engineering, a local technology integrator based in Fort Wayne, Ind., have demonstrated how collaborative innovation can contribute to business growth. This case study is one example of how manufacturers and technology integrators must work together to deploy Industry 4.0 technologies on the factory floor.

Smoker Craft Inc., headquartered in Indiana, possesses over a century of experience in crafting high-quality boats. Recognizing the significance of incorporating the latest tech into their manufacturing processes, they sought to improve their product quality, production efficiency and overall customer satisfaction. Embracing innovation as a means of staying ahead of their competition, they turned to Guide Engineering for support.

Guide Engineering is a local technology integrator in the same state that specializes in the design and manufacture of automation, assembly and test equipment. The firm has helped manufacturers adopt new technologies and automation for more than 60 years. This track record meant Guide Engineering was well-suited to assist Smoker Craft in their quest to modernize and automate their boat manufacturing process.

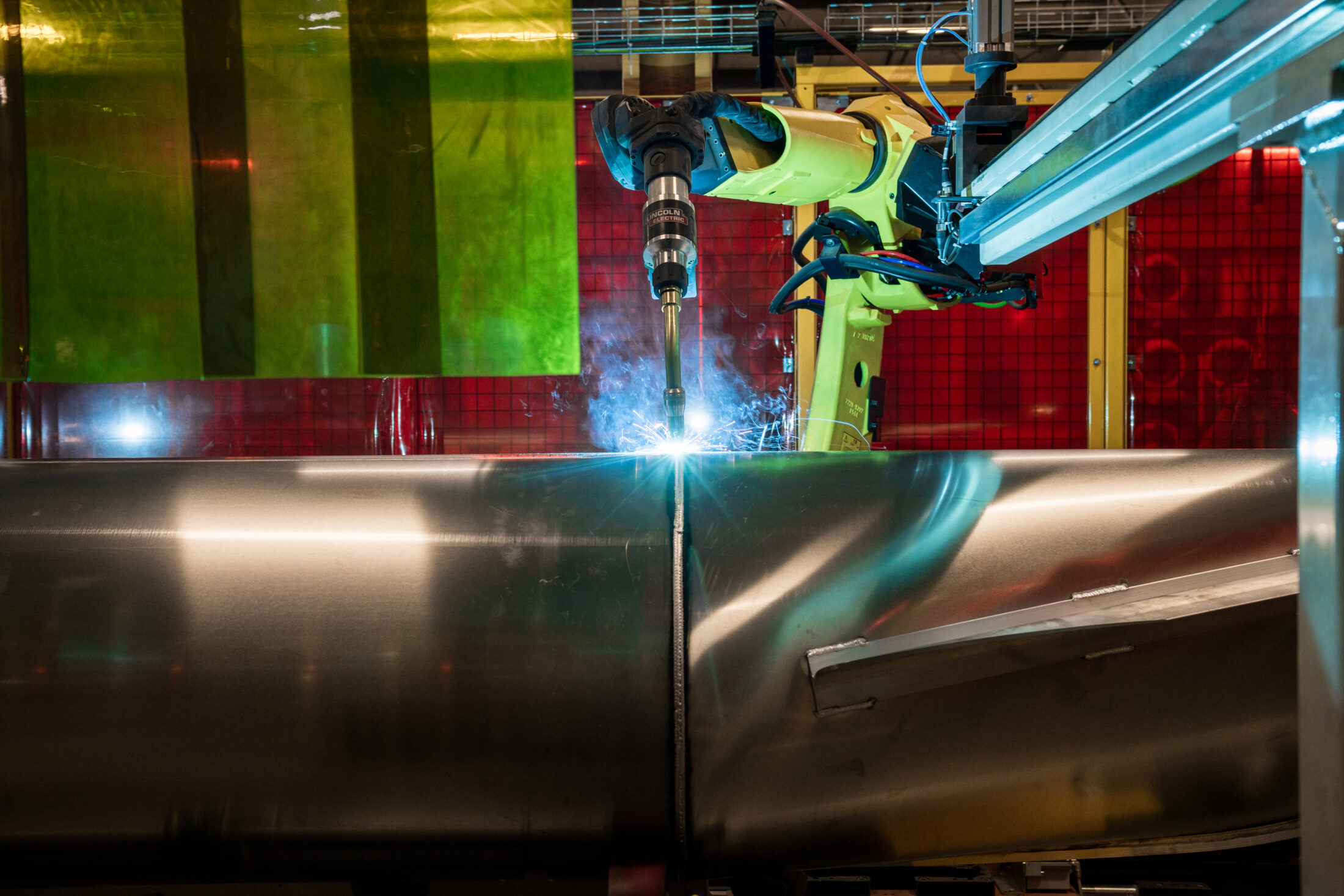

The outcome of this collaboration was determined to be the successful implementation and integration of a robotic welding system for Smoker Craft’s boat assembly process. The project would be designed to automate every part of the pontoon assembly, beginning with robots to form and weld the nose cones and align those with the pontoons on pontoon circumference cells. While Smoker Craft had recognized the transformative potential of automation to enhance efficiency and improve product quality, they are not experts in automation solutions, they are experts in making boats.

Collaborative Innovation: Working with a Technology Integrator

External experts like Guide Engineering bring a wealth of knowledge and experience from working with other manufacturing subsectors and clients. This experience allows them to draw on best practices from other sectors and apply them to the specific needs of the manufacturer they are partnering with. In the case of Smoker Craft, Guide Engineering was able to introduce a flexible automation solution that is adaptable to future Smoker Craft products and processes. It is not just for high-volume production of the same parts; the system can be adapted to future needs.

With the support of Guide Engineering, Smoker Craft successfully implemented a robotic welding system that transformed its manual welding process. Robots now execute welding tasks with precision and consistency, leading to higher product quality and significantly reduced production time. Smoker Craft can now meet growing customer demands while maintaining their decades-long commitment to product quality.

The partnership between Smoker Craft Inc. and Guide Engineering offers just one example of how a manufacturer can effectively integrate Industry 4.0 technology into their production processes with the support of a local technology integrator. It also demonstrates how collaborative innovation can drive business growth and ensure technology adoption reaches its full potential.

Learn more about Guide Engineering and its partnership with Smoker Craft from Josh Leitch, vice president of operations at Guide Engineering here.