ETI Implements a Surface Mount Technology System to Counter Supply Chain Disruptions and Improve Product Quality

Environmental Technologies, Inc. (ETI)

Case Study

Key Stats

Company History

South Bend-based manufacturer continues to produce technologies that “keep the wheels of commerce rolling by holding Mother Nature’s worst at bay.”

Environmental Technologies, Inc. (ETI, Inc.) is an original equipment manufacturer of sensors and controls for snow and ice melt across the US, with the NETCOM wave dehydrator line sold globally in 90 countries to keep telecommunications waveguides clean. ETI exists as an assembler of electronic components, while ETI Fabrication, another division of the parent company, provides fabrication and manufacturing services. Its third division, ETI CONTROLS, manufactures printed circuit boards (PCBs).

Specializing in snow and ice melt management, ETI provides pavement sensors, aerial sensors and both residential and commercial products. Its NETCOM product line provides waveguide dehydrators for telecom and satcom (i.e. guiding electromagnetic waves with minimal energy loss by restricting the direction of transmission). “A waveguide coming from some type of satellite system needs to be controlled to a specific dewpoint or moisture and our system provides a little added insurance,” Ben explained. “The system is pressurized so we can tell if our units are working hard or not. If we’re losing pressure in the system at some point, there might be a leak. That area has been very robust for us.”

Ben Crawford, the now president and CEO, brought more than 30 years of manufacturing leadership when he acquired ETI in early 2018. Back then, the company had some 25 employees. But in 2021, largely due to a major rebranding and redesign of the company, there are more than 60 employees. Soon after the acquisition, Ben realized that the production of printed circuit boards needed to come in-house to reduce ETI’s supply chain risk and help the organization meet its on-time delivery goals. At one point, the firm was outsourcing up to 90% of its printed circuit boards to out-of-state manufacturers in Michigan, Illinois and California.

The Project

An audit of ETI’s supply chain raised questions around the acquiring of printed circuit boards and the resiliency of suppliers.

“As we went through 2018, I learned a lot more about the business and integrated myself more and more,” Ben said. “Working with our whole team, we went through strategic planning. We had some concerns. A lot of concerns. A lot of the supply base wasn’t very sophisticated. There were significant risks to our business, particularly in the fabrication of printed circuit boards.” Our company approached a very large, publicly traded company for a quote on the work, and was told, “Hey, we’re going to exit the fabrication business. Would you guys be interested in purchasing our assets?”

“So we did,” Ben recalled. “We bought the assets and moved to a brand-new building in May 2019.” Now ETI had a new business, which Ben said, “quickly demonstrated its value, and by 2021, the business had grown some 600%.” Where ETI had typically purchased printed circuit boards through a small group of suppliers, making only necessary alterations in-house, the supply chain issues during the COVID-19 pandemic changed the equation. “Everybody wanted you to pay cash up-front,” Ben explained. “They were putting you in a headlock. While we had in-house capability to perform board alterations, we had never made our own boards.”

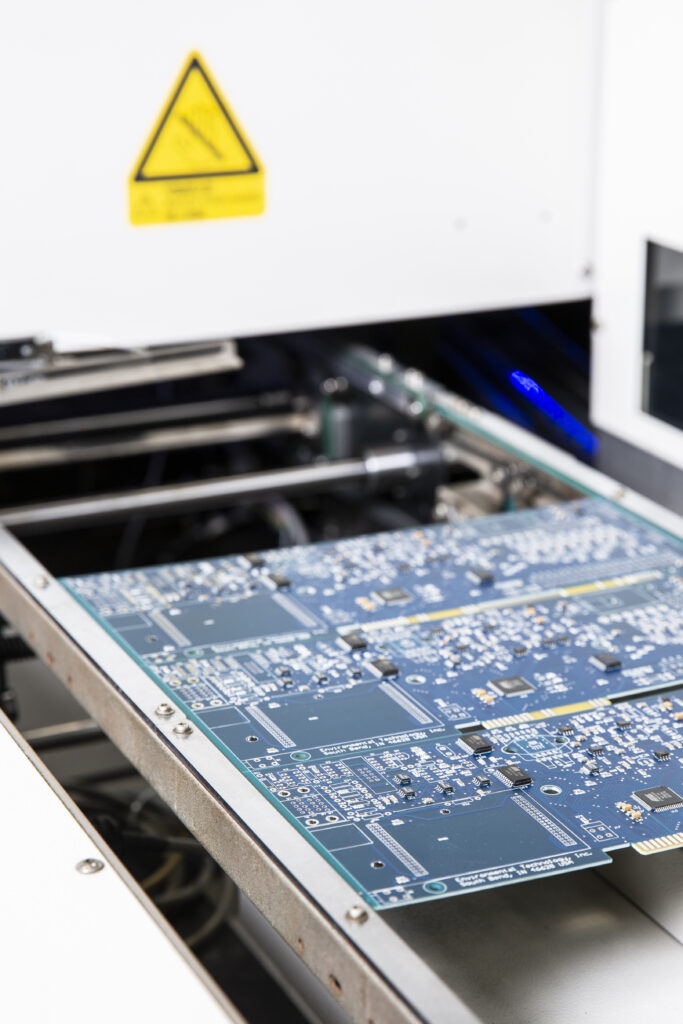

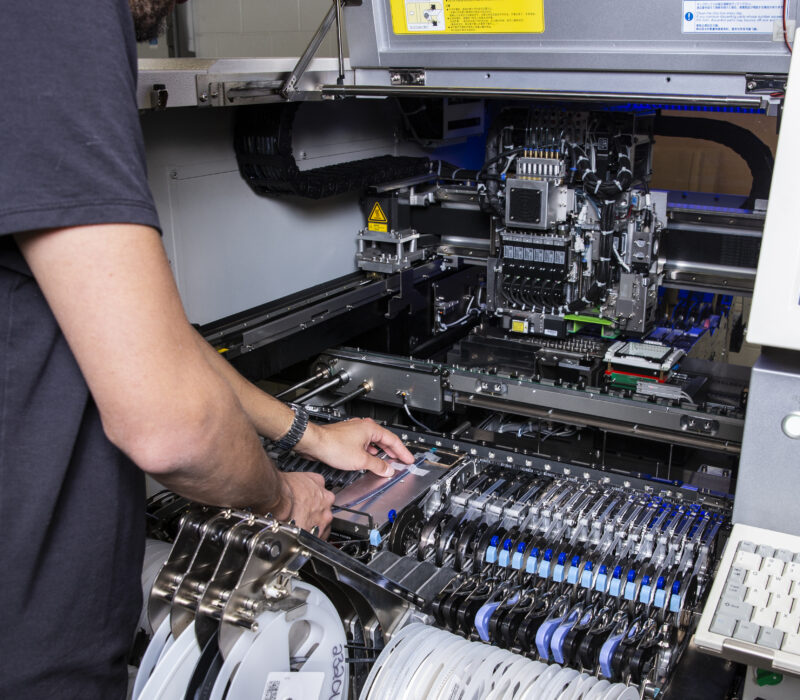

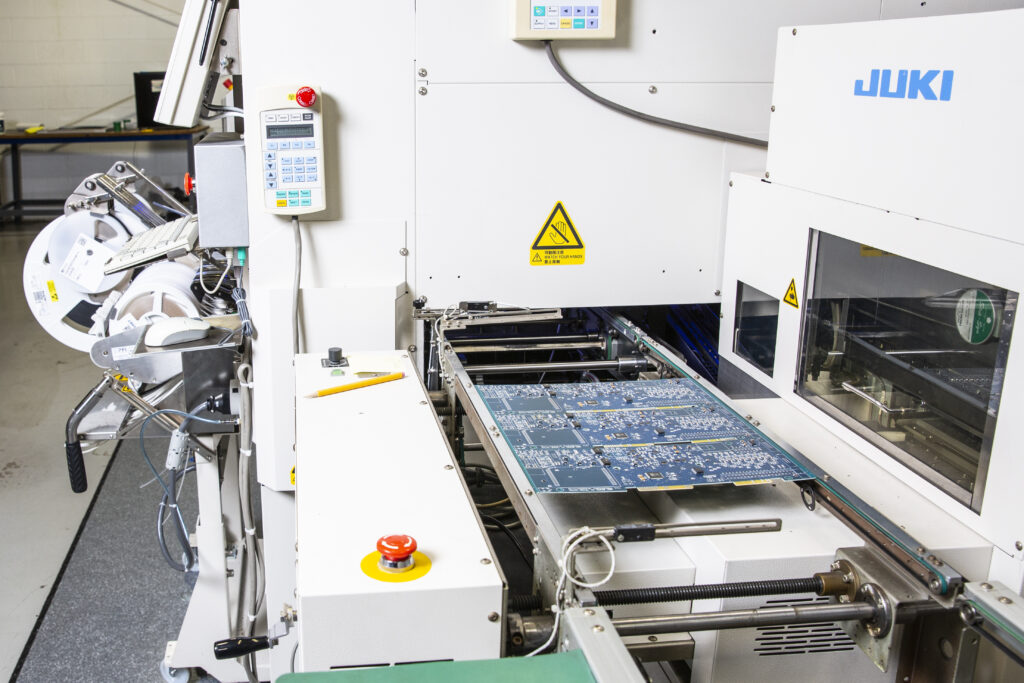

ETI CONTROLS implements Surface Mount Technology with an automated pick and place system to manufacture and assemble printed circuit boards in-house.

“While it was high risk, we made the decision to control our own destiny. We would manufacture the boards ourselves with a Surface Mount Technology system (SMT),” Ben explained. With the SMT in place, the biggest achievement was the ability to get those PCBs 100% optically inspected, with no need to rely on other companies to provide a quality product.

“It was a huge addition for us,” Ben said. “Today we manufacture roughly 12,000 boards for ourselves each year. Before, it was very costly to procure the boards and we were paying premiums. One supplier even put out a mass email to all its customers saying they had X amount and the highest bidder would get it all.”

The project according to Ben is a supply chain resiliency project. “Especially as we expand into private label products, and engineer new designs in-house, it really puts us in a much better position to grow,” he said.

Manufacturing Readiness Grants (MRG) provided by the Indiana Economic Development Corporation and administered by Conexus Indiana are available to Indiana manufacturers willing to make capital investments to integrate smart technologies and processes that improve capacity. Leadership at ETI felt a Surface Mount Technology system could counter supply chain disruptions and improve on-time delivery of its products; grant funding helped successfully kickstart the project.

Key Learnings

Bringing a new manufacturing process in-house is a team effort: from project management to purchasing and IT.

Among the insights gained during the technology adoption project was the unexpected trepidation at pulling the trigger to make the change from out-sourcing to in-house production. “It was a huge addition for us,” Ben acknowledged. “Today we manufacture roughly 12,000 boards for ourselves each year. That’s more than 3,000 different designs. “But we underestimated the purchasing component,” Ben said. “We’re now purchasing hundreds of different parts all the time. Receiving and entering all those parts into the ERP system required some fine-tuning.”

Ben also stressed the need to debrief everyone once the project is complete. “Once it’s complete, everybody walks away,” he said. “It’s important to debrief on the back end. Everybody should sit down and say, okay, what did we all learn. Because when we want to do it again, we want to avoid falling into the same holes. We did a lot of things well, but some things we just didn’t anticipate.”

Continuing to expand in-house production is on ETI’s strategic roadmap.

Currently, only a relatively small percentage of the PCBs ETI uses are produced in-house and increasing that number is top on the agenda. Expanding into new markets and producing custom and specialty controllers are also planned, with leadership convinced the company can meet the cost of overseas production and be extremely competitive. “The business is performing very well and growing,” Ben said. “We’re going to see a lot of specialty controller manufacturing happening right here. I think the business will explode once people realize they don’t have to leave Indiana to get this done.”

He credits the Manufacturing Readiness Grants program with getting the project off the ground and into production as quickly as possible. “This project would never have happened as fast as it did without the grant funding,” he said. “The grant gave us money, but it also gave us encouragement. It gave us confidence. It changed the whole scope of the project and allowed us to adopt the technology faster. Speed is a weapon in business, right?”

ETI continues to grow and train its workforce following the smart technology investment.

The SMT system was really the first smart technology the company had ever installed, according to Ben. Most of the work was assembly, and the epoxy line was manual. “This is the first piece of super advanced equipment,” he said. “I’m sure there was some anxiety in the workforce, but now there’s a great sense of enthusiasm. We’ve invested in the business, we’ve made it through COVID-19, and things are changing. Our employees are excited to have a new role in the company and learn to work with the new technology system.”

Regarding workforce training, both the SMT line provider and ETI provide training opportunities. ETI ensures its employees are certified to Initial Production Check (IPC) standards, which are developed by the Institute of Printed Circuits. “When we began, we had about 25 employees,” Ben said. “Now we have around 60 employees. As we went through all the changes with COVID, adopting new technology, and implementing a new manufacturing process, not one person missed any salary or got laid off. And we really pride ourselves on that.”

“This project would never have happened as fast as it did without the grant funding… The grant gave us money, but it also gave us encouragement. It gave us confidence. It changed the whole scope of the project and allowed us to adopt the technology faster.”

Ben Crawford

President & CEO at ETI, Inc.