Hoosier Crane Service Company Finds MRG Can Provide Time as Well as Funds to Accelerate Innovation

Hoosier Crane Service Company

Case Study

Key Stats

Company History

In its 3rd decade, Hoosier Crane Service Company expanded its successful service business, joining the ranks of Indiana’s small- to mid-sized manufacturers with new automation technology.

Tom and Cherie Schmidt founded Hoosier in 2002, opening the doors with 4 employees. Twenty years later, that number had grown to 85, and today is nudging 100. It remains a family owned and led enterprise, with Todd Cook as CEO. The company began as a crane service and repair company, and grew to include sales of parts and accessories, and eventually the design and manufacturing of custom overhead cranes. Director of Operations Kaitlyn Miller distinguished the company’s focus on overhead cranes from “the kind of cranes that you normally see at building construction sites.” Instead, she said, the cranes Hoosier services are permanent equipment found within a factory where they assist in material handling in an assembly process. “These are permanent fixtures,” she explained. “They are structural systems — electrical, mechanical systems that provide material handling within the factory.”

Primary business and operations began and remain in Elkhart, Indiana, with branches now in Fort Wayne, Indianapolis and Valparaiso. The company is considered an expert in the overhead crane field and also provides crane engineering, training and testing services.

The Project

In an expanded building with floor space to spare, Hoosier management considered bringing metal plate processing in-house to improve its customer service needs.

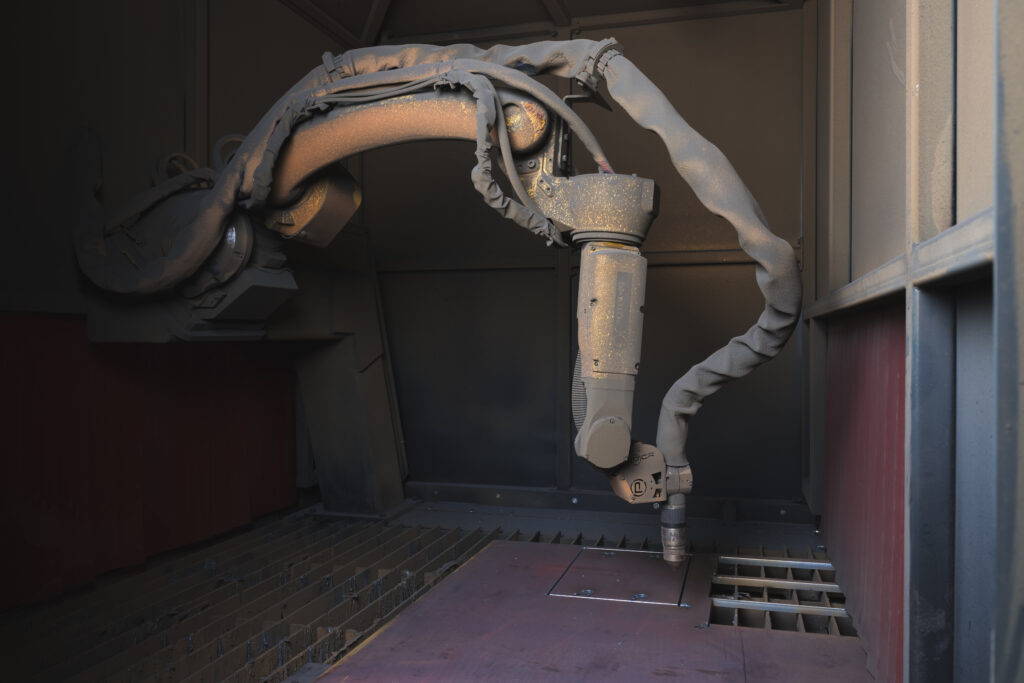

“We were using outside vendors to support that part of our manufacturing,” Kaitlyn said, “We have very high performing vendors, but our customer’s emergencies don’t always translate to our vendors. We want to provide the highest level of service to support our customers and, if a customer has an emergency, we didn’t want to have to rely on someone else to perform to that emergency.” Hoosier initially researched simpler CNC plasma tables to in-house the fabrication of structural steel plate, but with ample available floor space, leadership’s progressive growth approach, and the potential of financial support through a Manufacturing Readiness Grant, they soon expanded their search to include more advanced equipment. The decision was made to invest in a Prodevco PCR31 7-axis robotic cutting machine. It uses a Hypertherm XPR high-definition plasma cutter and a Fanuc multi-axis robot to perform various beam and plate processing operations.

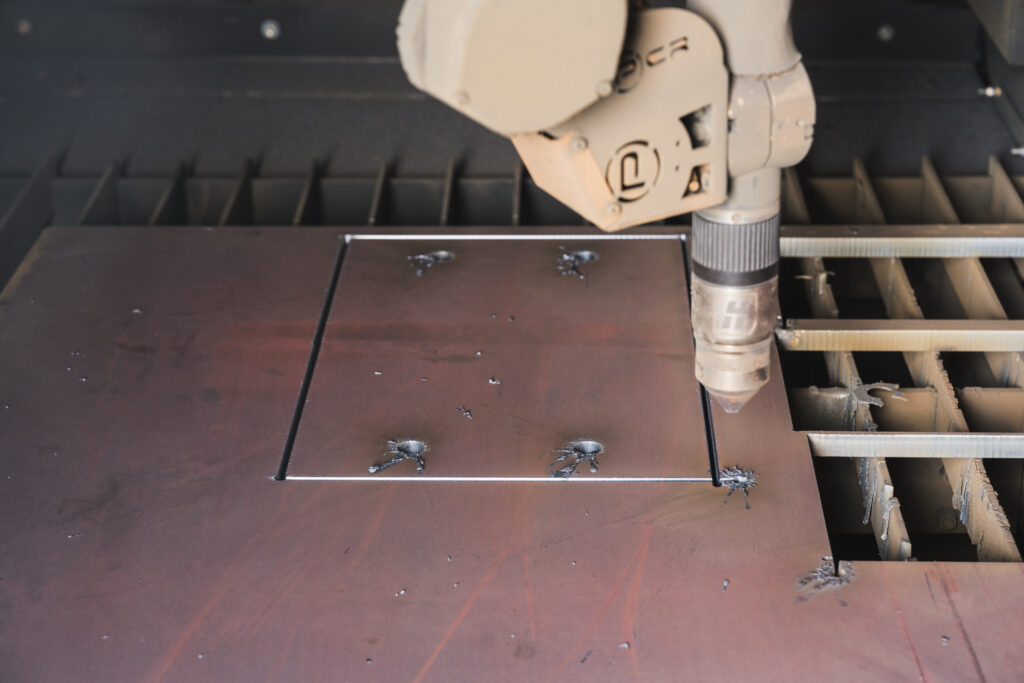

Hypertherm’s True Hole technology is a key aspect of this equipment. As Kaitlyn explained, this proprietary technology improves the quality of a cut, resulting in bolt-ready holes that don’t require a secondary machining operation – saving time and money for manufacturers. Traditional plasma cutting often creates a conical or concave hole pattern. The 7-axis robot adds a rotational aspect to the robot, she also explained, which enables bending of the robotic arm to work around objects without the need to reposition the workpiece.

This plasma cutter was a ground-breaking purchase (in fact, this Prodevco machine sold to Hoosier is only the 4th of this style the manufacturer has built) and as expected it has allowed Hoosier to manufacture more overhead crane parts in-house, including crane accessories, below-the-hook devices like pallet or vacuum-powered lifters, and other structural products. “Customer service is central to our business model,” Kaitlyn said, “so we’re always eager to streamline our manufacturing to better serve our customers.”

The plasma cutter has revolutionized the existing beam and plate machining processes at Hoosier Crane, too. Previously, Hoosier was processing 500 tons of steel annually with manual cutting, drilling and coping operations, the sum of which required a significant amount of floor space. The new 7-axis robotic plasma cutter operates in a smaller footprint, bringing all of those operations into a single piece of machinery, and frees up Hoosier’s highly skilled labor force for more complex and cerebral tasks. “In the long run, this project is just a small part of a larger investment of around $4.5M in our manufacturing facility in Elkhart,” said CEO Todd Cook. “We expanded by adding 14,600 square feet of manufacturing space to accommodate the expected increase in work volume. Despite our move into manufacturing, providing excellent customer service is the core of our culture. This is just a modest step toward a future full of automation-powered operations. This investment will not only help us solidify our position as a top provider of overhead crane equipment and services in the Midwest region, but also across the country.”

Manufacturing Readiness Grants (MRG) provided by the Indiana Economic Development Corporation and administered by Conexus Indiana are available to Indiana manufacturers willing to make capital investments to integrate smart technologies and processes that improve capacity. With the help of a $200,000 MRG, Hoosier Crane Service took the leap to enhance its custom manufacturing capabilities with a 7-axis plasma table.

Workforce Implications

With a highly skilled workforce in place, concerns about the potential that a robot might eliminate jobs just wasn’t an issue.

The oft-repeated concern about “Oh, you’re replacing a job with a robot” didn’t really arise at Hoosier. “Our team is really very highly skilled,” Kaitlyn said. “To be able to free up some of those smaller tasks with a robot allows us to look toward more complex projects and better use those skills in the workforce.” They look at the robot as “just another member of the team — an apprentice,” she said. Their skilled team has grown as a result, too – Hoosier added a new engineer to focus on the plasma table’s operations a month after it arrived.

Shared Learnings

Ground-breaking technology can be the solution to unique needs.

When Hoosier’s leadership selected Prodevco’s 7-axis robotic cutting machine, they were well aware of potential risks surrounding such an advanced purchase – but their unique manufacturing needs posed a large reward for the ideal machine. Prodevco is a structural equipment manufacturer in Ontario and was breaking into a new sector with innovative solutions. For Hoosier, that differentiated them from other equipment suppliers. There were other steel processing solutions they could have chosen, “But we were really back to floor space again,” Kaitlyn explained. “We needed something that was going to combine plate processing and linear processing in one location. Prodevco was about the only one we could figure out that met those requirements. From other suppliers we heard, ‘You could probably do it a little bit,’ or ‘You could probably add that feature.’” Prodevco had the right tool for the job and actively worked with Hoosier to implement programming to accommodate their unique situation. “We’re all learning together, and we weren’t able to find anything that unique that fit our needs.” The company also had a technician on the Hoosier site for 2 weeks, working alongside the operator while training and setting up the machine.

Prodevco offers timely support through the machine’s remote diagnostic features, allowing Hoosier to instantly message the vendor, connect them remotely to a manufacturing camera feed, watch the machine operate and monitor its screen. In the early days of establishing the equipment, “We found a particular machine process that was critical to us,” Kaitlyn said. “We were struggling with that process, and, only 4 weeks after they commissioned it, the vendor came back and helped us reprogram their equipment to support that process. They came here and helped us troubleshoot that, tailoring the program a little closer to our needs.”

One other bit of advice she shared: “I wish we had spent a little more time just practicing. We’re starting to run production parts now, and it’s fine, but we really didn’t dedicate the time top to bottom – from engineer all the way through to operator – to completely understand the machine as a group.” She described what she termed the difference between “working in and working on something.”

“Initially, we were in the ‘working in’ process. We were doing it because it was our job, and that was what we needed to do today,” she said. “But if we could take a step back as a group and ‘work on’ why we are doing this and how can we improve this, and what makes this better, and how can we improve that,” she explained. “We still get those opportunities, but I wish we would have dedicated more time as a group at the onset to try some things out together.”

Some of the “working in” day-to-day issues are still happening, and solutions are being innovated. Hoosier is revamping the CAD program they use to produce their production drawings. “I think we knew issues like this would happen,” she said. “We just weren’t exactly sure how much, or why, or how. Now that we are in production, we’re revamping our CAD procedures to better integrate with the machine.” Those were issues that were anticipated, but difficult to resolve and work through until they were a tangible obstacle to overcome. “This is a digital transformation,” she said. “It’s not just a fabrication tool we brought in; it’s a fabrication tool with a lot of technical features. We’re working with those, in the spirit of ‘working on’ versus ‘working in.’”

The Manufacturing Readiness Grant doesn’t just help grantees finance innovation; it can accelerate a smart manufacturing transition’s timeline.

The MRG, Hoosier found, can provide breathing space to consider and work on unforeseeable issues that arise with new technology — to find root causes and work through them with the entire team. “The grant didn’t just help us buy the equipment,” Kaitlyn said. “It helped give us the space to explore and learn and optimize the equipment. If we needed to justify that investment entirely off our internal budget, we wouldn’t be able to take time for the exploration phase. It’s so efficient that we can continue to evaluate and optimize our procedures and work on internal skill building while meeting our current production requirements.”

Ultimately, she advises small and mid-sized manufacturers to take the leap. “There’s no reason not to. It’s exciting to be on the leading edge of our industry with advanced technology,” she advised. “I don’t believe a lot of our competitors in industry are trying the next thing, saying ‘why not’. I go back to Tom and Cherie Schmidt and that little shop with 4 employees. They started with a ‘yes, we can,’ attitude that has driven growth and innovation over our 22 years. And even with those big challenges, they’ve maintained that mentality of ‘yes, we can do something beyond what we’ve been thinking about.’”

“That attitude resonates through our entire company,” she added. “It’s challenging at times to be a service company that also manufactures equipment. But it’s who we are. The partnerships we create with our vendors, our customers and our employees, is the key to where we are today, and where we’re going.”

“Customer service is central to our business model – we’re always eager to streamline our manufacturing to better serve our customers.”

Kaitlyn Miller, Director of Operations