2 Manufacturing Readiness Grants, 2 Approved Projects – an Indiana Company Takes the Next Steps into Smart Technology and Automation

Metal Forming Industries

Case Study

Key Stats

Company History

The original Metal Forming Industries (MFI) was a 1991 spinoff of a Delaware, Ohio company, purchased by Indiana entrepreneur Ron St. Clair’s St. Clair Group in 2012.

“When I acquired the company in 2012, its single product line — power semiconductor bases — was declining,” Ron said. “It had about $2,000,000 in revenue a year and was at the end of its product life cycle. That product line is at about $200,000 in revenue a year now; we began to expand the company to reach different customers and continue a successful operation.” He attributes that growth to an expanded market made possible by the incorporation of technology that transformed MFI into a modern smart manufacturing company.

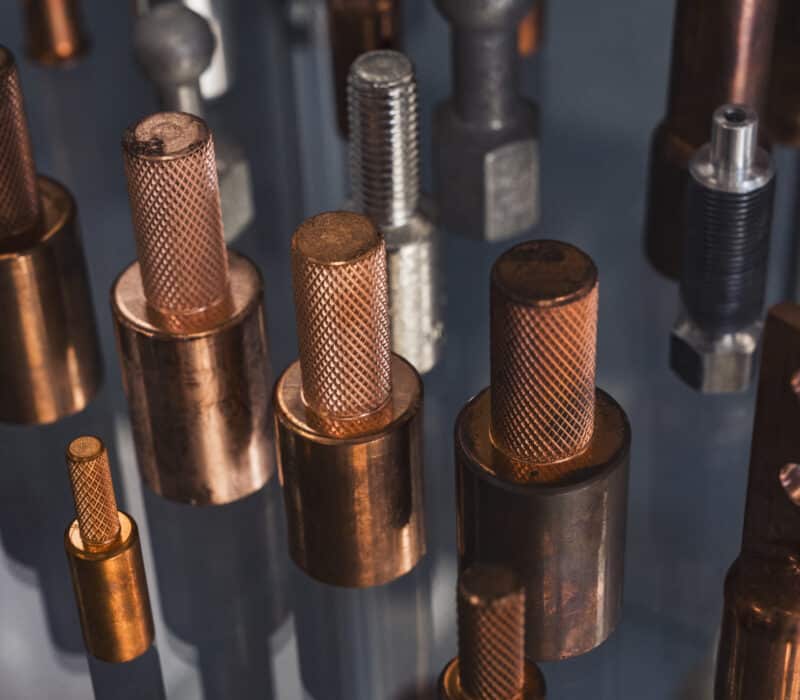

Today, MFI is a nonferrous-components manufacturer supplying material components like specialty battery terminals, grounding ferrules and semiconductor bases for subassemblies that go into yet other assemblies for a variety of industries. The company’s manufacturing property remains in the small west-central Indiana town of Russellville (population 500) and its corporate functions are in Lebanon, Indiana where Ron serves as CEO. It maintains an all-Hoosier workforce of 25. Ron notes, “I’m very proud of our team here. We took a company that should have been out of business in 2014, and now we have a thriving business. We’re unique. I can only think of 1 other company in the U.S. that can do all of that together.”

The Projects

MFI presented a compelling strategic justification for both its 1st and 2nd grant applications.

Their initial grant project was for a digitally-enabled hydraulic forming press which not only enhanced production capabilities for new market entry, but also provided a platform for the future introduction of COBOTS to their manufacturing processes. In the short-term, the project expanded MFI’s product offerings for the high-voltage transmission and firearms industries by offering an increased press stroke to manufacture physically longer parts.

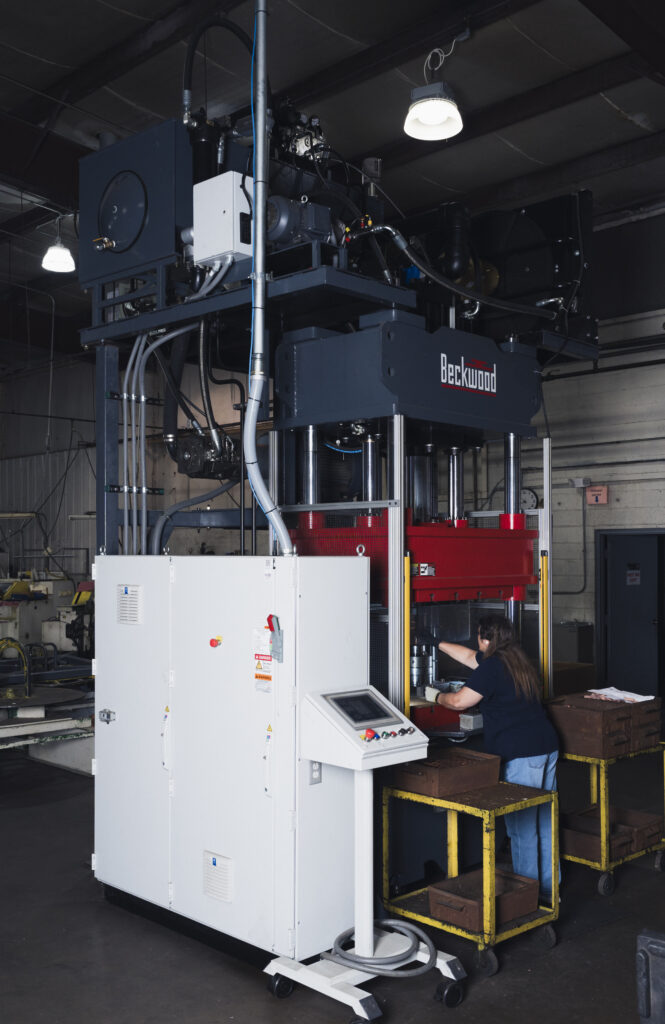

This first MRG award supported $85,000 of the total $270,000 investment in a custom Beckwood 200-ton hydraulic press with on-board preventative maintenance capabilities. The anticipated benefits were doubling labor productivity, reducing part production costs by 25%, and reducing tool breakage by 50%. Up-skilling employees through IVY Tech’s METC program allowed for efficient use of the system’s programmable controls, IIoT capabilities, and eventual cobot programming. “We were already the sole supplier of the components we produced for the majority of our customers,” Ron said. “The new press is helping us secure new customers that also single source with us.”

Their 2nd grant application built upon the successes of the 1st project and was for the addition of a Tsune automated bar-stock circular saw. This saw replaced the existing labor-intensive manual cutting process and allowed lights-out material processing over 2nd and 3rd shifts. “This automated cutoff saw feeds directly into the press from our first MRG project,” notes Ron. “We’re actually entering a new market segment that I wouldn’t be able to enter without these automated and connected capabilities between the two machines. We’re looking at a faster run rate out of both, which also helps reduce our cost.” The 2nd MRG application was approved for $82,500, supporting the total $164,833 equipment purchase price.

Though over a year apart, the grants and projects combined to accelerate a technology upgrade strategy – transforming MFI’s business via new market entry and new product offerings.

A year and a half after their 2nd project was approved, both projects were installed and operating as a single entity. “We’re using this equipment and going after different customers,” Ron said. “The hydraulic press with its Programmable Logic Controller (PLC) allows us to do much faster development and to move into some additional product lines.”

In each project, MFI’s chief engineer was provided details about what the project was to accomplish, including the target market segment that equipment would cater to and what kind of components need to be produced with it. For the hydraulic press, Ron wanted a U.S. manufacturer with IIoT diagnostic capabilities, and the engineer’s recommendation was the Beckwood press assembled in Ferguson, Missouri. “I wanted the manufacturer’s maintenance to be able to dial into our controller and diagnose most issues remotely,” Ron explained. “I didn’t want to have to pay $500 for a service call, plus travel time and expense to have someone come out and tell me we just need to turn a switch a different way. The ability to diagnose remotely was an extremely important benefit on such a complicated piece of equipment.” Additionally, the press’s fluid health monitoring system independently monitors oil contamination trends, including early warning indications that allow for predictive maintenance operations. On-site maintenance is provided twice annually to review safety systems and general performance for any other early signs of wear.

MFI’s digital adoption journey doesn’t end with its grant-enabled projects.

Due to the repeatable nature and high amount of part/material positioning for many of MFI’s processes, Ron also prioritized compatibility with collaborative robot upgrades (Cobots) for the hydraulic press and automated saw. “There’s a lot of setup… That’s why I’m now looking at a cobot, to see how you can train one to run with the parts presented to it while other people are doing the types of work that a cobot can’t do.” MFI is investigating a way to introduce COBOTS to their workforce through a unique and relatively inexpensive learning experience: “There’s a company that offers a 4-week learning session – you can lease a COBOT to bring to your facility and let your workforce experience it, play with it. See it can go here. It can grab that part. It can do other things. Put a little smiley face on it and just bring it in. It’s not dangerous.” Leasing a COBOT with proper tech integrator guidance allows manufacturers to see the most compelling potential use cases for one. As Ron puts it, “You just want to make sure it doesn’t get rolled over in a corner and ignored.”

Manufacturing Readiness Grants (MRG) provided by the Indiana Economic Development Corporation and administered by Conexus Indiana are available to Indiana manufacturers willing to make capital investments to integrate smart technologies and processes that improve capacity. Metal Forming Industries upgraded its technology and brought its unique combination of skills and services to Indiana customers with the help of 2 MRGs totaling $167,500.

Workforce Implications

MFI’s goal was centered around community impact – to pay workers a good rate, with good benefits, at a job where people don’t have to drive an hour to go to work.

“We didn’t do these projects to lay anyone off,” Ron said. “We did them to reduce the labor content and upgrade the skills of the people already here using newer technology, similar to what you have on your mobile phone.” The parts MFI manufactures are long lead time parts – 6 to 18 months from first talking with a potential customer to completing the sample stage and finally beginning production. As with most smart manufacturing transitions, there were questions from the workforce. Having only a high school diploma, some employees were concerned that they would be required to re-apply for their positions and wouldn’t qualify for more technical jobs. “Come on in,” Ron told them. “You can be an operator. We will train you. You can have a career here, and the more you learn, the more you’ll earn.”

Ron echoed the experience of other executives who have directed MRG projects through to completion in stressing the importance of early and open communication with the workforce to explain what the projects do — and don’t — mean for them. The human aspects of MFI’s manufacturing processes remain central to success. “When they ask, ‘are you going to fire me?’ the answer is ‘No.’ We make that direct. You’re not going to get fired because of automation. You’re going to stay here and we’re going to increase output. There won’t be a Ronnie the Robot running around that can do what you can do. You’re going to be tending to that robot and making sure it functions properly. This is our company: metal forming in Russellville, Indiana, with Indiana labor.”

Continued workforce education is critical to the success of an expanding manufacturer, he said. “Our folks are not trained in school about the allocation of capital or about the practical aspects of industrial technology. We need to explain that we’re going to keep the doors open. Being a small manufacturing company makes it easier to provide that reassurance, because of the trust we’ve built with our workforce.” The sooner people realize things may be changing, the better to begin addressing the issues. That can go a long way toward understanding, acceptance and enthusiasm. “They can have a good job, paid a good rate with good benefits,” he added, “and they don’t have to drive an hour to go to work. They can drive 5 minutes in their golf cart and work in a nice, close, competitive area.”

Shared Learnings

Some of the best advice MFI’s CEO can share is to take advantage of the benefits available to manufacturing companies in Indiana, for both capital equipment and educational investments.

From State government to local counties and cities, there is support for manufacturing in Indiana, Ron said. He is especially appreciative of the State’s support for small manufacturers – “That’s good manufacturing,” he said. “By good, I mean small, family-supporting jobs right here in Indiana. That’s what my management team and I look at and we want to keep them. I like small communities, rural communities. I like to keep jobs here and to pay people fairly, and I want to help them gain the knowledge and experience they need to succeed at those good jobs, good careers.”

Ron encourages employers to look beyond a 4-year post-secondary educational focus to find a solid workforce and courses that can up-skill those employees for the demands of smart manufacturing. “It’s not easy,” he said. “High school educators are trying to make a difference, but it’s like swimming upstream,” he said. “The schools may never ask how many students you send to the electrician program, or the CNC program. Indiana manufacturing is kind of the best kept secret.” He champions the practical education provided by Ivy Tech regional campuses and the Haas Technical Education Center through Vincennes University. The Hass Center caters to non-traditional adult students including military veterans, who can use their military benefits to enroll in courses.

The MRG program was initiated to incentivize small and mid-sized Indiana manufacturers to accelerate their transition to Industry 4.0 smart manufacturing capabilities. What manufacturers may overlook, though, is the degree of support that is also available through local city- and county-supported economic development organizations – not necessarily in dollars, but in information, connections, introductions and other advantages. Because MFI was focused on expanding its focus in both product line and geographical markets, Ron and his management team were investigating opportunities for both and ways to allocate capital. “I didn’t expect the Manufacturing Readiness Grant program,” Ron said, pointing out that his initial interest wavered when he understood the grant-writing requirement. “The Greencastle-Putnam County Economic Development Executive Director Kristin Clary gets all the credit for me moving forward with the application. She came and she bugged me. ‘It’s not that hard. Just tell them what you’re going to do and why you want to do that and how the grant can assist you.’ And it wasn’t that hard. Here’s what we need. Here’s why we need it. Here’s why we need both parts of the package and how we can stage it in 2 different but connected projects.”

Ron admits the application walks the applicant through not only what information is required, but how to organize and explain it to the evaluation committee. “The grant process typically takes 3 to 4 months,” Ron said. “It takes a commitment and a holistic view.”