Indiana Furniture Takes a Giant Stride into Industry 4.0 with Automation

Indiana Furniture

A Case Study

Key Stats

Company History

Competition Hasn’t Slowed Indiana Furniture’s March to Adopt Technology.

On St. Patrick’s Day in 1905, a group of Jasper, Indiana, residents came together to establish a local solution to the need for good jobs in the growing Dubois County area. Their plan: leverage the abundance of hardwoods growing in the surrounding forests to manufacture quality furniture in response to the needs of a growing nation. Today –116 years later –Indiana Furniture is thriving in Southern Indiana as a privately-owned company boasting descendants of some of those same founders as owners. “Since 1905, we built furniture the whole time,” said Indiana Furniture’s Vice President of Operations Chad Nord. “The look and the feel and the customers have changed, but it’s always been furniture.” With four facilities in Dubois County, Indiana Furniture remains a home-grown success, and Chad leads it happily. “I can get up in the morning and by 10 o’clock, I’ve been to all our factories. I love that.

The area is one of two office furniture manufacturing clusters in the nation (the other is in Grand Rapids, Michigan), and friendly competitors are located next door and down the road. But competition hasn’t slowed Indiana Furniture’s march to adopt technology. The company already utilized five robots and recognized the MRG as a vehicle to navigate its next step into automation.

The Project

Automation Augments What Was a Manual and Monotonous Production Process.

Adapting to the changing atmosphere of today’s office spaces, with companies seeking more collaborative office designs, Chad and the rest of the leadership team were looking beyond the “chair that sits behind the desk,” toward innovative answers to help the company meet increasing demand for quality seating that responds to contemporary work behaviors. Capacity was key to the solution, and automation was key to capacity. Even the COVID-19 pandemic hadn’t stifled the increasing market appetite for office seating. The company’s highest seating volume ever materialized in 2020.

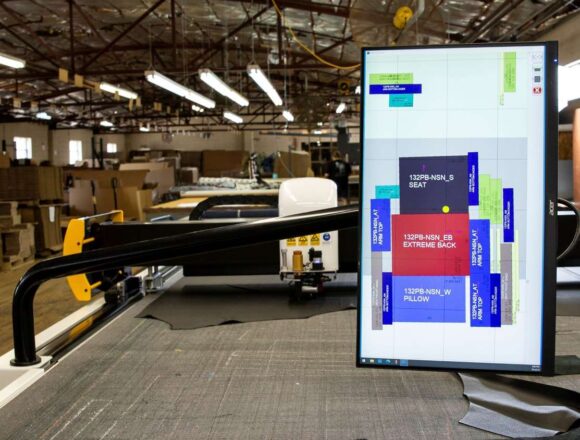

The cutting room floor was the next logical place to seek automation solutions. “The only thing automated about cutting,” said Chad, “is a set of scissors with a little cutting wheel. The rest of it is laying out templates and tracing around them.” Automating a job that depends on employees knowing how to lay out the pieces to get the optimal amount of coverage from a fabric, and how to make sure all the graphical patterns align, is just a fraction of the equation.

The rest of the process is the monotonous cutting, and Chad acknowledges that there will always be some fabrics even the most technologically advanced machine can’t match. “But if the machine can cover 80 percent, those folks who are the experts will lean in and solve the rest of the problems,” he said.

The new equipment does that. But even that success can lead to a certain amount of frustration. “When I go out on the floor,” Chad said, “nine times out of 10 the machine isn’t running. It’s just so fast that it runs out of work.” He knows what the fix is: get the leather digitized. “We’re doing this massive transformation and change, while running faster than we’ve ever run,” he explained.

Manufacturing Readiness Grants (MRG) were available to Indiana companies willing to make operational investments to integrate smart technologies and processes that improve capacity, as well as companies willing to invest in health care manufacturing technology to support critical COVID-19 response. The timing was ideal for the Indiana Furniture Seating Operation’s biggest step yet onto today’s technology-savvy factory floor.

Project Impact

More Time to Problem Solve and Take on New Responsibilities: Automation Frees Existing Workforce From Tedious Jobs

No machine can replace every employee in every position. “You hear about automation killing jobs,” Chad remarked. “But it’s really freeing up humans to do the human work.” The machine, he said, can do the tedious jobs much faster than a human. “But there are always going to be some fabrics that, because of the pattern, the machine just can’t figure out how to get all the pieces to match.” And that, he said, is just one of the areas where a skilled workforce is essential. “My number one problem throughout my career in manufacturing has been not being able to find enough people,” Chad said. “There is no level of automation that can change that. All we can do is help ease the situation.” His advice: “I always say, get someone who’s willing to show up and willing to learn, and we’ll teach them any job.”

Humans help the technology solve some problems, he explained. Leather is an example. “Leather is a significant part of our volume, and there is no such thing as a pattern or standard that’s coming off of a cow,” Chad said. He mentioned scars, brands and other natural characteristics. It takes a partnership between the skilled worker and the automated cutting machine to succeed with leather. “We have a big table with a camera above, we mark all the defects and take a picture to digitize it to scale with its exact size. When it is time to cut, the machine will pull that digitized image. We specify what chair needs to be cut from that piece, and the machine lays that out and starts cutting.”Success depends on the machine working without a pattern, just a blank canvas that can go to any shape, any orientation. “The equipment just has to fit as many pieces in there as possible to get the best yield.”

Key Learnings

Industry 4.0 Requires Rethinking Workforce Deployment.

Don’t be afraid to deploy your workforce in new ways. The new automation piece has dramatically changed how a part of Indiana Furniture’s labor force operates, and Chad encourages other leaders to be open to that. “In the last seven weeks, we’ve set four all-time records for how much seating we’ve put in a box in a week,” Chad said. “Implementing changes while producing at record levels made it difficult, but we’ve got the model down now. At the beginning of one of these pushes, we put together a cross-functional team with one project leader, the maintenance team, product engineers, process engineers and production team. They all have a shared vision. I help solidify the vision, put the team together and then I get out of the way.”

Understand Your Company’s Specific Technology Needs, Build a Roadmap, and Don’t Fall Victim to the “tech Hype Trap”.

“We’ve been talking about upgrading and modernizing our cutting process for two or three years, so we knew we needed to do it,” Chad said. “The question was just how and when. With an increase in volume this year and a key new contract, we knew the time was right. We needed to do it, but we didn’t know if we should do it during a pandemic with an uncertain sales outlook.”Finding out about the Manufacturing Readiness Grant program tipped the scales to motivate the purchase. “We went after the grant and decided that, if we were awarded the grant, we were going forward. It really made that investment the right size to where we knew we can pull it off right now,” he explained.

Securing a new, large contract factored into the plans for this big leap forward in technology, too. “It just took our traditional thinking on a rocket trajectory. We knew how to do it, and all of this came together,” Chad said. “We’ve been taking care of things like redundancies in some of our more manual equipment like sewing machines, and adding capacity, but you cannot easily automate those processes.” Attacking cutting was the logical next step in automation for Indiana Furniture. With planning, projections and investment all pointing toward a positive decision, Chad made one last assessment. “Don’t be driven by the hype or whatever anyone else thinks is cool,” Chad advised. “Figure out what your biggest problem is, and then go find a technology solution that can help fix that problem. If it doesn’t fix people’s problems then it’s not worth it, especially in a small company where every project needs to be a winner.”

“In the last seven weeks, we’ve set four all-time records for how much seating we’ve put in a box in a week… Implementing changes while producing at record levels made it difficult, but we’ve got the model down now.”

Chad Nord

Vice President of Manufacturing, Engineering and Quality at Indiana Furniture