Support from Manufacturing Readiness Grant Helps Entrepreneurial Holic Foods Ramp-up to National Presence with Automation

Holic Foods

Case Study

Key Stats

Company History

It wasn’t a long-time plan of Antony (Tonio) and Frances Torres to become food entrepreneurs, but the irresistible green sauce at their local taqueria changed their future in unexpected ways.

Husband and wife Tonio and Frances were regular customers at a local taqueria near their Middletown, Ind., home. One very big draw for the couple and other locals was a crave-able green sauce served in the restaurant. When the business was sold, the new owners made some menu adjustments resulting in the disappearance of that favorite green sauce. Saying they were “devastated” when they could no longer enjoy that sauce, Tonio decided to duplicate the sauce as closely as possible at home. When he believed he had matched — and maybe even improved upon — the recipe, Tonio shared the product with friends and family. Their enthusiasm convinced Tonio there would be a market for fresh, globally inspired flavors. In 2013, he and Frances launched Holic Foods to offer “clean-label, bold-flavored sauces, dips and condiments that taste so good they are naturally addictive.” Soon, Jalapeñoholic sauce was joined by Tahiniholic and Honey Aleppo Holic — each “all-natural, totally crave-able, spicy and velvety.”

“We founded the company in 2013,” Tonio said, “but commercially launched our first product in 2018-19, and since have transitioned to marketing not only our own brands, but also as a contract packer producing proprietary sauces, dips and condiments for clients.” Barriers to entry in the food industry are significant and include setting up mass production and automation, he explained. There are significant capital challenges and global food safety certification is required by grocery chains for marketing efforts. “It’s one thing to have a proprietary recipe for your own sauces, but when you start taking on bespoke production for other companies, you need to have a lot of equipment and capacity,” Tonio added. “What you make for one company is different from what you make for another company. You need flexibility and control equipment and all the automation that goes with that.”

At the time, Tonio managed multi-million-dollar retail banking platforms for a major international financial organization. That experience influenced his approach to entrepreneurship, starting with a Purdue University partnership. He worked with the university’s test kitchens and culinary experts. “One of the things they recommended was to start small and build a brand with local farmers’ markets. But that limits growth potential and, frankly, the ability to get scalable growth,” he said. He considered using a co-packer, but couldn’t find a fit. In the end, a large supermarket chain approached Holic Foods, asking if the company was interested in private labeling for its stores. After negotiations about the chain’s production requirements and Holic Foods’ production capabilities, a compromise was struck. The chain would provide evidence of its immediate interest in contracting with Holic, but not promise that interest would survive the one-and-a-half years Tonio calculated would be required for Holic to ship the needed quantities.

Tonio and Frances agreed that, if they were serious about making Holic Foods successful, they should accept the challenge. “If I was to leave my banking career, it needed to be for something we could scale,” he said, “something that could substantiate a serious career. And that’s what we did.”

The Project

MRGs were designed to recognize that entrepreneurship in manufacturing is especially challenging, requiring not just developing a product and brand, but building from scratch a platform to produce that product.

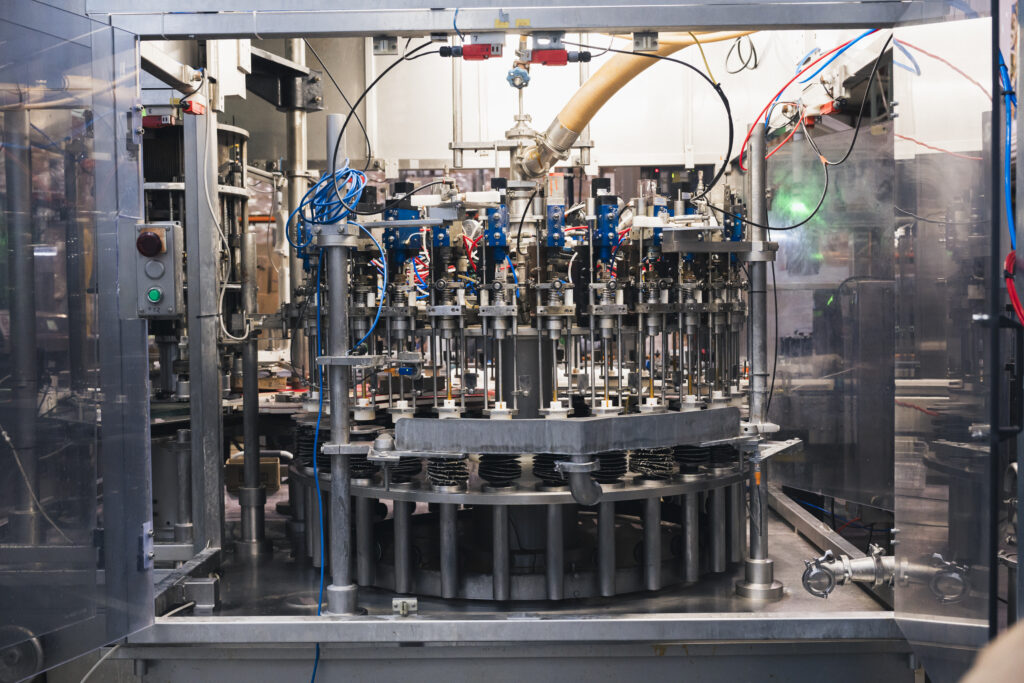

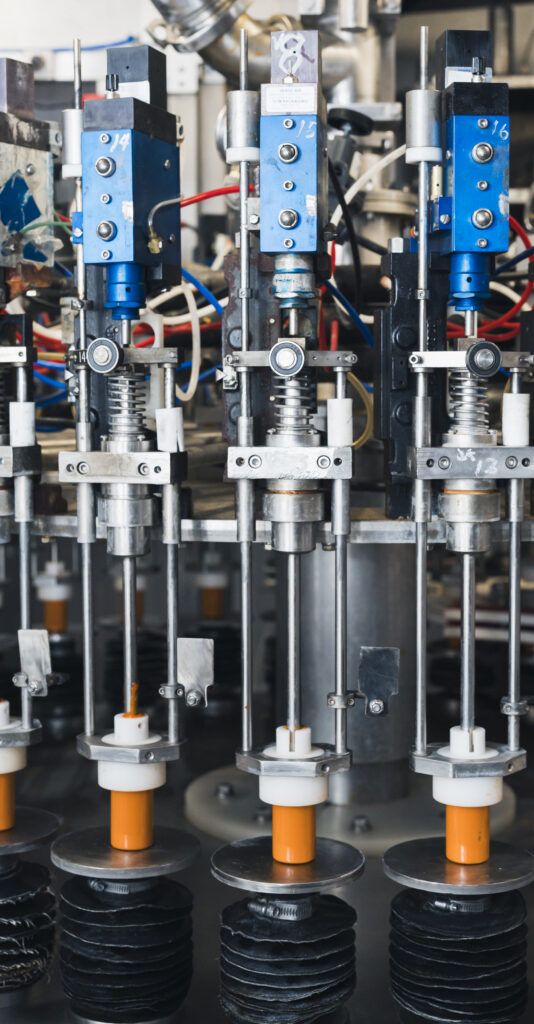

For Tonio, the opportunity, vision and timing aligned with the launch of Holic Foods. “When we first started, we wanted a semi-automated process,” Tonio said. They purchased a defunct biofuels facility, and, he recalled, “buying the place and seeing it empty and saying, I don’t know what I’ve just done. This is so big. I’m never going to use it all.” Still, Holic needed to get the product out, and the building was the best available option. “We could process and cook in our 250-and 500-gallon tanks, but it was all on paper.” Everything was measured by hand and, after a continuous batch process, went to the filler, capper, inverter, cooler and bander. With the existing technology, the process produced 60 bottles per minute, which seemed like a lot to Tonio. “Zero to 60 bottles a minute and we’re producing a bottle every second.” It was less a manufacturing plant than a high-capacity commercial kitchen, but was quick, integrated and working well. Holic was building a great reputation and, by April 2020, had product in 1700 stores of the initial grocery chain, as well as a major big box chain and a few specialty grocers.

Then COVID hit. People were shopping online, and only for staples. New brands were not a priority. Holic, like so many young brands, was at risk. “Because of our reputation, we had an opportunity to launch a secondary brand, called Pantry Basix, with a general merchandise retail chain,” Tonio said. “To take that leap, we decided to put in a secondary line — more automated, high-speed and giving us the ability to compete both on volume and cost in that marketplace. With help from our MRG, we brought in systems that allow us to program recipes and automatically pump ingredients in the desired levels, making sure it’s mixed properly.”

With the second line, production capacity increased from the initial 250- and 500-gallon tanks to 1,500- and 2,500-gallon tanks – from 60 bottles a minute to 250 bottles a minute. Another planned piece of equipment may increase that capacity to 400 bottles a minute. “We went from producing 20,000 bottles a day to more than 150,000 bottles a day, and the cost to produce came down,” Tonio said. “Because of the volume, clients are looking at us and asking, ‘What is your capacity, and how do we grow with you?’ That puts us in a phenomenal position.”

Manufacturing Readiness Grants (MRG) provided by the Indiana Economic Development Corporation and administered by Conexus Indiana are available to Indiana manufacturers willing to make capital investments to integrate smart technologies and processes that improve capacity. Founders of Holic Foods launched their new company in an empty manufacturing space and purchased enough semi-automated equipment to begin production; a $200,000 MRG helped them expand capacity with a second, automated line.

Workforce Implications

Despite warnings that technology will replace human workers, Holic Foods and the Middletown community have found the opposite to be true.

“As we increased smart technology on our second line, we reallocated existing staff and brought on more staff,” Tonio said. “As we grow, we’ll bring on more staff for specialty positions and front line. We’ve been able to promote people. Someone who used to be on the line is now handling shipping because we used to have four trucks a week and now have 20 trucks a week. Now we need a shipping manager and an inventory manager. Now instead of a “sort of engineer,” we need an engineer on site to help with maintenance and keeping the equipment running.” That largess extends to the community, as well, he said. “We now fund two other entrepreneurs who have their own businesses in software and hardware, and equipment maintenance and repair. The impact is just getting started, but it’s substantial and a lot has happened already.”

The increased productivity, he said, helps salvage wage growth within the community. “Our community of Middletown has been phenomenal in working with us,” Tonio said, adding that Henry County, too, has been tremendously supportive. “We need growth and employees,” he added. “Automation helps you compete on a national scale. It solidifies the fact that you’re going to be a long-term business and continue to grow in the community and grow the wage market.

Holic’s co-founder and CEO shares what he’s learned in his entrepreneurial experience.

“If you think about the lifecycle of entrepreneurship or small business, you come in and you wear every hat. You’re trying to get it all done all the time,” Tonio said. “I’ve been lucky. Most entrepreneurs get into business because they’re great at making donuts. They love making donuts, but they may not have experience running a business. I know how to run a business and I just happen to be in the sauce business right now. That afforded me the ability to grow. But as you grow, your business gets more and more complex. You need to specialize and have different individuals with different skills, whether it be engineers, marketing people, account people or office roles. The first thing an entrepreneur needs to do is get the work done. Get it done right and get it done with strategy and organization. My job is to have a vision and a strategy for the future.”

It’s important to be thoughtful enough to pivot, he advised. “If we had been steadfast on “Holic naturally addictive foods” and didn’t think about pivoting our business to take advantage of co-packing opportunities, we would have missed out.”

“Clients are looking at us and asking, ‘What is your capacity, and how do we grow with you?’ That puts us in a phenomenal position.”

Tonio Torres

CEO of Holic Foods