Century-old Oscar Winski Adopts a Robotic Welding System, Brings First Proprietary Product to Market, and Expands Business by Reshoring Production

Oscar Winski

Case Study

Key Stats

Company History

Founded in 1907, Oscar Winski continues under the leadership of 5th generation Winskis.

Oscar Winski’s manufacturing story began with opening his first scrap metal business with his son, Louis, in Lafayette, Ind., in 1907. Today, that company retains its original entrepreneurial spirit, with 5 of Oscar’s descendants actively in the business. Each generation has found its own way to innovate and thrive – some via supply chain refinements and solutions, others through business expansion, and others through technology adoption.

The Oscar Winski company of today has diversified to encompass several industries and sectors. Across multiple locations in the Hoosier state, they have distinct businesses in commercial and industrial recycling, new steel and aluminum coil processing, global supply-chain management services and contract fabrication. Their fabrication business, Lafayette Steel & Aluminum (LSA), fabricates components and assemblies for commercial trailer manufacturers and other original equipment manufacturers (OEMs), many of whom are reshoring components from China where they had originally outsourced this work due to lower labor and supplier costs. The tides of global sourcing changed as the world began to exit the pandemic presenting a unique window of opportunity.

LSA utilized a Manufacturing Readiness Grant to grow an already extensive list of advanced machinery and skills working with metals, flat-rolled steel and extruded aluminum shapes. Through these enhancements, LSA has been able to accomplish their dream of launching their own proprietary product line, Konik Heavy Duty Products, while continuing to serve the growing needs of their fabrication customers.

The Project

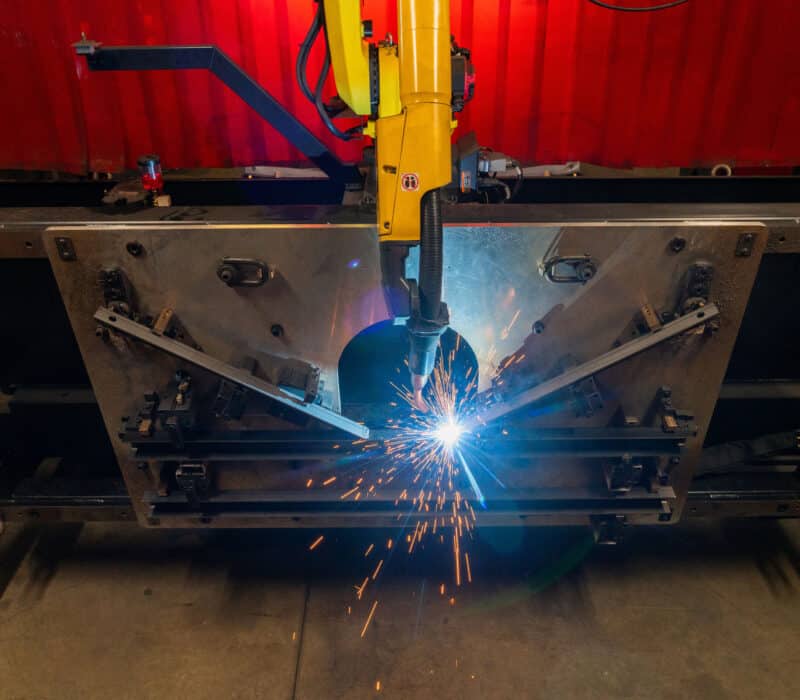

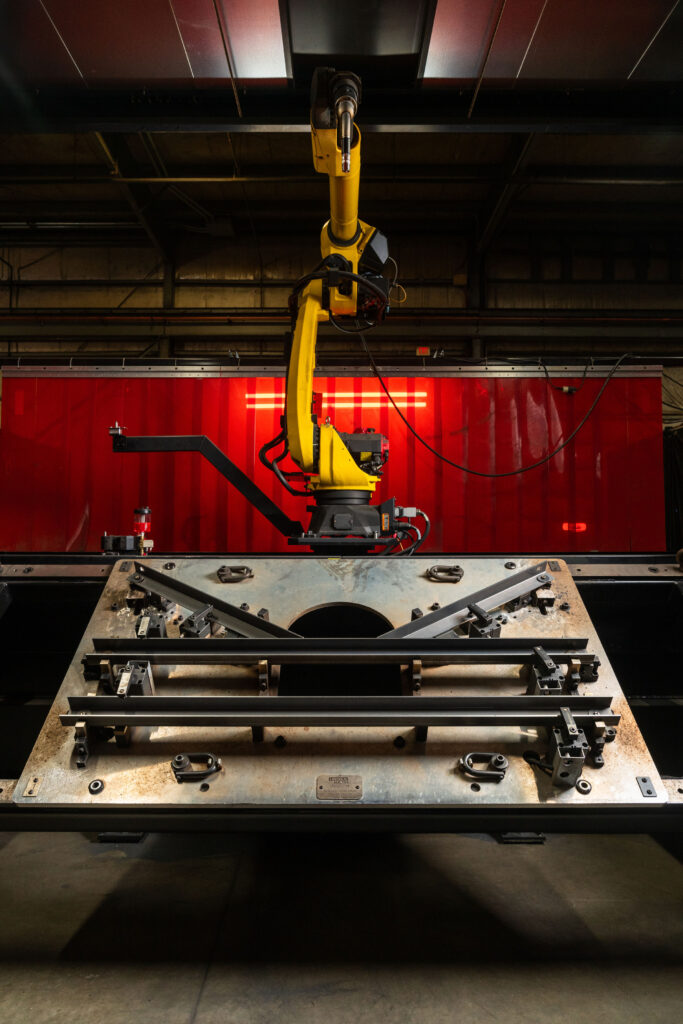

Oscar Winski started the post-pandemic era with the adoption of a robotic welding system.

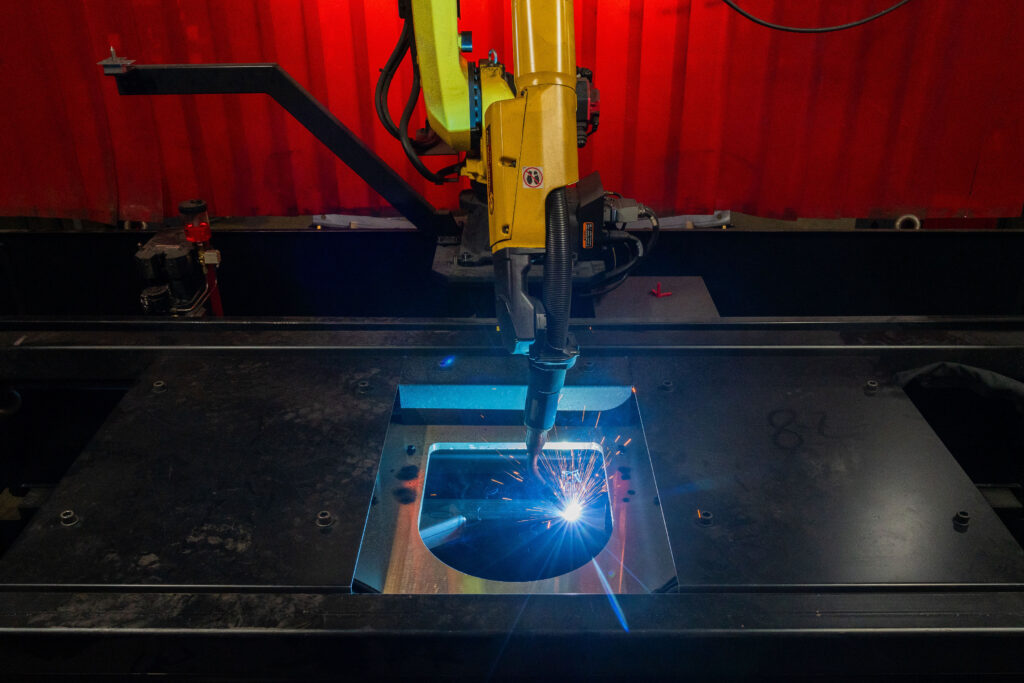

LSA fabrication customers realized their dependence upon offshore manufacturing partners was becoming increasingly risky from global logistical disruption, rising costs and escalating geo-political tension. They needed to realign their supply chains and wanted to do it with a reliable local source, still maintaining the cost competitiveness they enjoyed overseas. The key to earning back considerable market share and maintaining cost-competitive services was advancing the company’s welding capabilities and capacities through the adoption of a robotic welding system. The MRG-supported project was designed to accomplish that goal. “Prior to our investment in this new equipment, our capability in the world of welding was very limited and very manual,” said Executive Vice President Alex Bluestein, a member of the Winski family. “With the new equipment, we can do so much more. We’re able to bring in higher complexity of parts and components and offer a larger value proposition to our customers by absorbing more work and completing it more cost effectively because of the technology that – historically – was not an option for us.” In addition to these expanded capabilities, higher standards of quality are being achieved consistently at a nearly flawless level.”

LSA fabrication can now offer competitive product solutions for these OEMs not only on goods historically sourced from low-cost global sources, but also what may have been produced in-house by their customers. “We can supplant their foreign source and free up their internal capacities, reducing their supply-chain risk and bringing their overall cost down. This is a big win for our customers and for LSA. Without the new technology, we would not have been able to do this.”

Manufacturing Readiness Grants (MRG) provided by the Indiana Economic Development Corporation and administered by Conexus Indiana are available to Indiana manufacturers willing to make capital investments to integrate smart technologies and processes that improve capacity. A Manufacturing Readiness Grant helped Hoosier company Oscar Winski earn back customers by reshoring production.

Shared Learnings

Teaming up with a local technology integrator was essential for a successful project.

One thing Executive Vice President of Fabrication Paul Isaacs believes streamlined the process was choosing and teaming with a very good technology integrator. “One was tech provider Lincoln Electric who helped identify the right equipment for the installation,” he said. “We didn’t try to do it ourselves.” Because LSA wanted to start small and learn how to automate, leadership chose a turnkey system “that gives us the opportunity to learn. We’ve seen things that we realize we want to change in our next installation.” At the end of the day, though, he is convinced that was the right way to tackle the project. “I wouldn’t change anything on the first go-around,” he said. “They brought the knowledge and the expertise. Now that we got our feet wet, we’ll ask more questions on the front end and better understand what we want out of the next technology adoption project.”

Alex expanded on that. “What I saw was by far the cleanest and best equipment installation we’ve ever done across the entire company. We have never installed something that went as smoothly and got us at production rates and volumes more quickly than this project. It was a strong confidence builder, and we know it doesn’t have to be painful and fraught with failures for us to move forward,” he said. “From installation and starting production, we were at 50% of what we wanted the first week, and 75% the second week. By the third week, we were at 100% of projections,” Paul reported. “It was an amazing kick-off and launch. It’s one of the best I’ve seen.”

Another critical piece, Alex said, was the MRG program. “It was really powerful to know the state of Indiana was behind us,” he acknowledged. “What the MRG demonstrated is that Indiana is proactively trying to help companies like us take that next technology step forward. The stars aligned with the availability of these funds. We also felt a responsibility to do it right, to live up to our end of the bargain and demonstrate an ROI for the state.”

The robotic welding system did not eliminate headcount, but it provided opportunities in workforce skills.

Like many companies embarking on a technology adoption project, Winski leadership was sensitive to the need to bring the workforce on board—to demonstrate that this was not a way to eliminate workers, but to invest in a better future for the company and its employees. In addition to spending previous months developing their manual welding talent and hiring a certified welding professional for improving best practices, the company was transparent in demonstrating the opportunities that would be available when the new equipment was operational on-site. “We transitioned a production operator into a technician based on his own willingness and motivation,” Paul explained. “The employee was operating a press brake where he demonstrated aptitude. Though he had limited welding experience, we approached him and he showed an interest in learning robot programming. When the robotic welding system came in, he applied what he learned in programming and he ran with it, becoming the project champion among his co-workers.”

Paul acknowledged that there was some apprehension among long-tenured workers early in the process, but overall, the workforce’s reaction to the project has been positive. “When employees see improvements and technological advancements, they know this is an organization they want to stay with for a long time. Overall, the workforce bought into it and there is a lot of excitement around it.” This excitement has gone as far as energizing the workforce regarding future prospects within Oscar Winski and creating opportunities for workers to participate in more cerebral, value-added tasks. “When they see investments being made and technology introduced, and when they see an opportunity to learn something new and become part of the business’s evolution, they feel a stronger connection to the company’s mission.”

“With the new equipment, we can do so much more. We’re able to bring in higher complexity of parts and components and offer a larger value proposition to our customers.”

Alex Bluestein

Executive Vice President at Oscar Winski