Primex Design & Fabrication Increases Capacity with an Advanced Digital Printer, Automatic Sheet Feeder and Custom Automatic Creasing Machine

Primex Design & Fabrication

Case Study

Key Stats

Company History

Primex Design & Fabrication is a wholly owned subsidiary of Primex Plastics, a 57-year-old company that provides custom packaging solutions.

Headquartered in Richmond, Indiana, the company grew from an initial plastic sheet extruder in a New Jersey plant. Its first expansion was to Richmond, Indiana in 1980, later opening operations in Georgia, Wisconsin, Nevada, Tennessee and the United Kingdom. Business Unit Director Doug Borgsdorf shared insights into the family culture driven by company ownership, “The business has always been family owned and operated. As a matter of fact, our President, Mike Cramer, started with the company 45 years ago as a factory worker. He worked in almost every one of those facilities before becoming president. It’s a good example of longevity and loyalty at Primex.”

The business started as sheet extrusion, Doug said, and “if you’re camping in an RV, our sheet goes into the wall and floors of the RV. If you’re paddling down the river in a kayak or canoe, that’s our sheet. We don’t necessarily make an end product with our sheet, but we sell it to thermoformers who form kayaks, canoes, paddle boats, plastic pallets and other such products.”

The company also operates as a sustainable operation, recycling some 240 million pounds of plastic each year, and putting it back into its sheet applications. Its plants in Tennessee and New Jersey make plastic colorants, compounds and additives. The fabrications group develops end use products from the original sheet. “And then with the recycling,” Doug said, “all of that comes back and we extrude into product that can go to any number of industries.”

The Project

From a manual, seasoned business, Primex leadership and employees adjusted, adapted and changed to keep the energy flowing with digital printer and robotic loading/unloading.

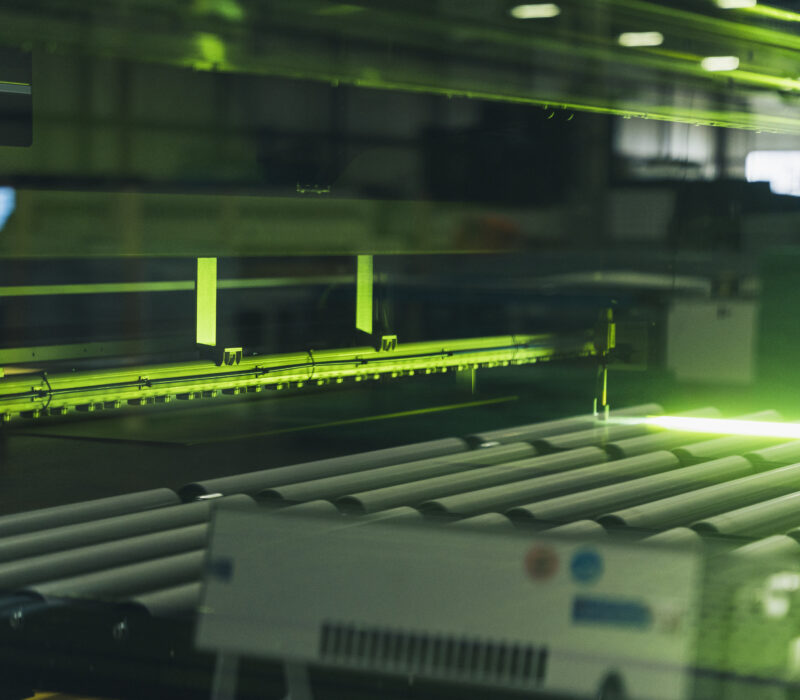

The Primex Manufacturing Readiness Grants (MRG) application began with one of the most advanced digital printers in North America, according to Doug. Because of the time and effort consumed in changing the previous digital printer from one color to another—2 people working for 6 hours—the company found it more efficient to outsource color runs to companies outside Indiana. The first investment under the MRG was to purchase the new advanced digital printer which, because of the speed of changing colors, significantly reduced the need to outsource printing.

Combined with robotic feeding capabilities for plastic materials to the CAD table, the new advanced digital printer has significantly increased production at the Richmond plant. “Our fabrication group can run anywhere from 100 to 120 SKUs a month,” Doug said, “and about two or three of them repeat next month, so it’s a very custom-oriented shop.” To explain the impact of those numbers, he said a single SKU can include nine different pieces, with a production run of anywhere from 50 to 10,000 for a major, big-box retail customer. The new robotic feeder takes on that repetitive task so employees can focus on the human jobs that enable the plant to maintain and increase that capacity.

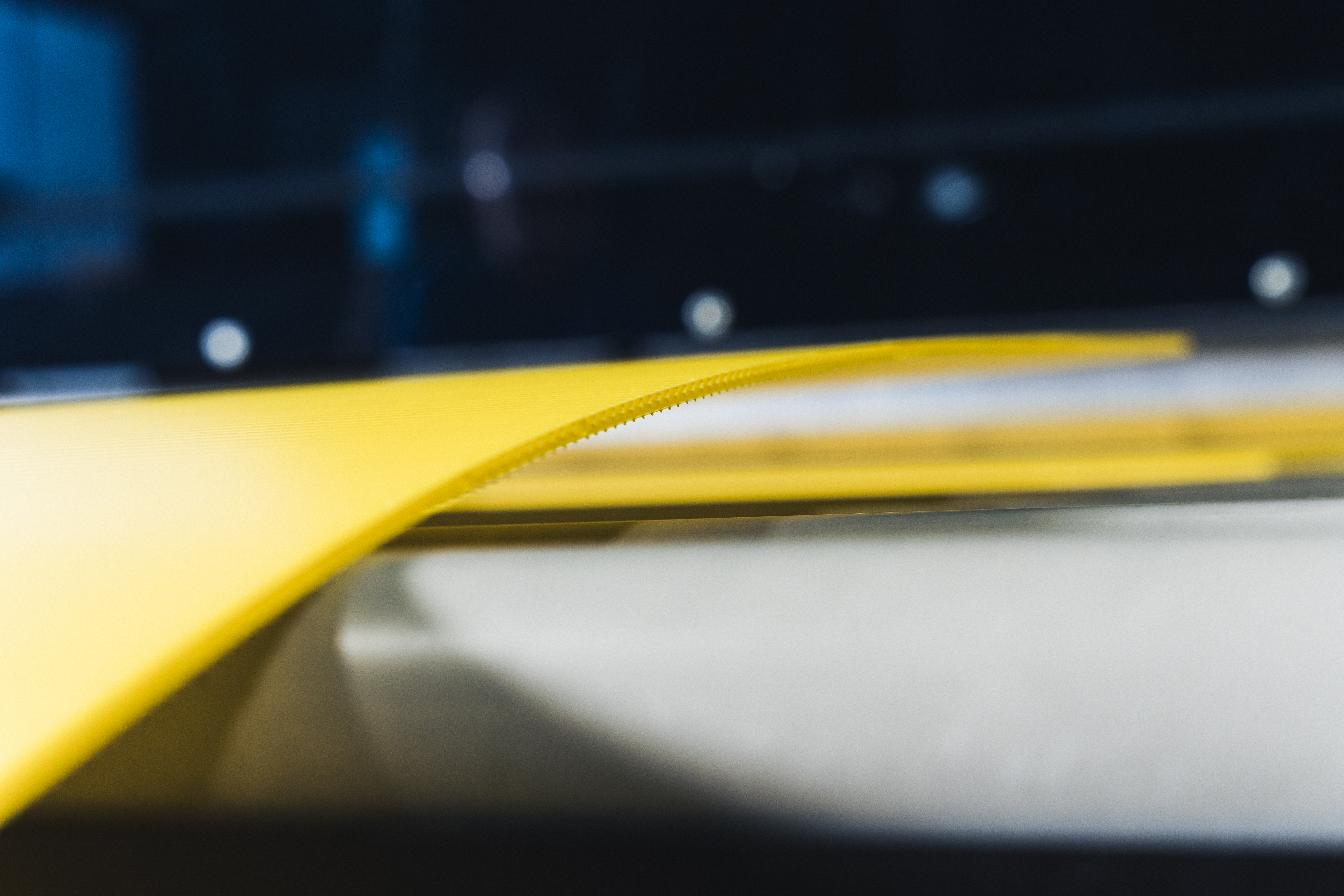

A custom-made automatic creasing machine rounded out the 3-part project.

Struggling to find a better way to engineer custom-made plastic products such as boxes, Primex found that the standard “fluted” sheets didn’t provide the flexibility or strength needed by its customers, and the strength of the advanced sheets proved equally problematic. Again, the solution came from working closely with four or five employees most familiar with the job. This time, a nearby supplier contributed to the solution, and together, Primex Design & Fabrication leadership, their employees and the supplier collaborated to custom-design an automatic creasing machine that, when integrated with the automated feeder on the CAD table, became a seamless operation.

On reflection, Doug said, “we were working with a fabrication group that had never used the material before, and a supplier that had never made such a machine before. We probably went through four or five reiterations. We had to deal with every small feature, like where does the foot pedal go? Where is the safety guard? And so on. In the end it probably took a few months longer than I would have liked, but the end product worked out well—so much so that we put in a second one.”

Manufacturing Readiness Grants provided by the Indiana Economic Development Corporation and administered by Conexus Indiana are available to Indiana manufacturers willing to make capital investments to integrate smart technologies and processes that improve capacity. Primex Plastics invested its MRG in workforce-initiated smart technology including a custom-designed machine that increased capacity and employee growth and satisfaction.

Key Learnings

Understanding today’s challenges is key to effectively using smart technology.

Doug believes understanding today’s challenges provides a map to eliminating roadblocks. “We can’t do the things we did a year ago or two years ago or three years ago. If we’re scared to adapt, or we think COVID is going to go away and everything is going to return to ‘normal,’ we’re not going to succeed,” he said. “Listening to our workforce and adapting and being creative in how we engage people is the key. Most people wake up each day wanting to be better off than they were yesterday emotionally, financially and physically. When you can engage them with new technology and ideas, they get excited to come into work and contribute to the company’s growth.”

He summed up his management philosophy: “We continue to transform and be crafty and creative on what fits for each individual employee. We communicate with our employees, and explain why we’re doing what we’re doing. If you’re not talking to them face-to-face, and just sending out a memo or putting it on a TV or computer screen, it won’t work.” And finally, “I don’t manage by committee. I value the committee’s input before I manage.”

Employees can keep the energy flowing in the business.

“We learned especially during the COVID pandemic, our employees rose up and helped keep the energy flowing in the business. They suggested to me that if we could automate the feed system to our CAD table, we could have those parts being cut while we’re working on the next project. If you’re standing there feeding sheets all day long, it’s repetitive and it’s boring. It’s not exciting and you’re not inspired. The employees suggested to me that we needed to look at how we could automate that process.”

The robotic feeding system developed from that concept, with Doug acknowledging that the employees knew and understood their jobs and how to make them function more efficiently. “Our employees stay with us forever,” he explained. “Most of them retire with us. They stay with us 20, 30, 40 years, and they were excited about getting new technology and putting it in place. They did their homework, and they said, ‘well, if I can do this faster, I can do this other job.’” Doug described it as what engineers call an “impulse function,” or hitting the system with a massive change that can realize capacity and capability that was previously unknown.

“It was a huge transformation,” he said. “COVID reminded us that the best decisions can begin on the factory floor with the people who actually do the day-to-day work.”

Leadership and workforce make a compelling case for mutual respect.

Doug said the factory floor has been “nothing but pure excitement,” and that Primex benefits from that attitude. “We work together,” he said. “No job is eliminated. Instead, we advance the job for the existing employees and they end up making more money. We pay based on cross training. When we add technology, we need to make sure employees know how to work it, because I’m certainly not going to go out there and do it. Our workforce knows that we’re investing in their business. We are a family business, and we want their son or daughter to walk in and work here. I think our last nine next level jobs—quality, supervisor, sample room—all came right from the factory floor. And it’s so exciting when you go out there and see a new operator on the machine who used to be in welding, and now is running the automated feeder for the CAD table, it’s exciting.”

When discussing equipment supplier training, Doug shared that Primex’s training process is to have the equipment supplier provide a training plan and two weeks of training, for all three shifts. “Every supplier that we bought equipment from has to give us the training package. I’m not signing off until I can sit with our people and have them show me what they’re doing.”

“Richmond is a blue-collar, manufacturing town. We know not everyone is going to run off and go to college. When they see the investments [in technology], the [workers] get excited.”

Doug Borgsdorf

Business Unit Director at Primex Design & Fabrication