Wood-Mizer Takes the Next Step in its Automation Journey, Adding Innovative Collaborative Welding Systems to Automate its Low-Volume, High-Mix Applications

Wood-Mizer

Case Study

Key Stats

Company History

From its launch in the back of a Speedway garage, Wood-Mizer has grown to include a global headquarters in Indianapolis and manufacturing locations around the world.

Like so many entrepreneurial stories, the one written by Don Laskowski and Dan Tekulve began with an idea sketched on a piece of scrap paper and advanced by building a prototype. But not all ideas—not even the best ones—manage to take a concept and develop it into an organization that 40 years later boasts more than 100,000 customers in 120 countries. The two men’s legacy continues today with the name “LT” paying tribute to the first letter of their two last names. In fact, their partnership was so successful that it is rare in the sawmill industry to hear either ‘Don or Dan’ mentioned alone.

Their revolutionary idea was to reduce the difficult and often dangerous work of milling raw wood into lumber, making the process more widely available and affordable. They would accomplish that feat by creating an entirely different kind of sawmill than those manufactured by competitors. A key advantage to their idea was increasing the sustainability of the forests that provided the lumber. The solution was a sawmill that could travel to the forest where the logs were harvested and be safely operated by any trained operator. It would recover more boards from every log with less energy, and could even salvage fallen trees that larger sawmills often left as waste on the forest floor.

“Wood-Mizer machines can be used by a small operator as the basis for a sawmilling enterprise or by a master wood crafter to create a new product from a home workshop,” said Wood-Mizer’s North America President Darryl Floyd. “Today hobbyists, farmers, custom and commercial sawyers, woodworkers, furniture makers, pallet companies all rely on Wood-Mizer for their business operations or to realize their dreams.”

Following the founders’ mission not only to sell machinery, but to “be servants to our communities and grateful stewards of our natural resources,” all Wood-Mizer products are built to last with premium steel, powder coat paint and the highest quality components. Quality control is strict, innovation is consistent, and technology is embraced and incorporated readily.

The Project

Wood-Mizer Deploys Several Collaborative Welding Systems to Increase Flexibility and Automate its Low-Volume, High-Mix Applications.

While growth was constant at Wood-Mizer through the years, the COVID-19 pandemic that started in 2020 and continued to affect the world through 2021 and 2022 saw business at Wood-Mizer accelerate. After expanding its new plant in Batesville, Indiana, Wood-Mizer leaned into technology adoption and purchased its first traditional robot welder. The system cost well into six figures and required substantial programming and workforce training. “They take up a pretty big footprint, and you have to protect the entire area around it,” Darryl said. “They’re not mobile, you can’t move them around and you can’t redeploy them in various ways. At the same time, our business really took off in 2020. Trying to find people was difficult, and we knew we had to do something besides continuing to have people manually weld many parts in the factory.”

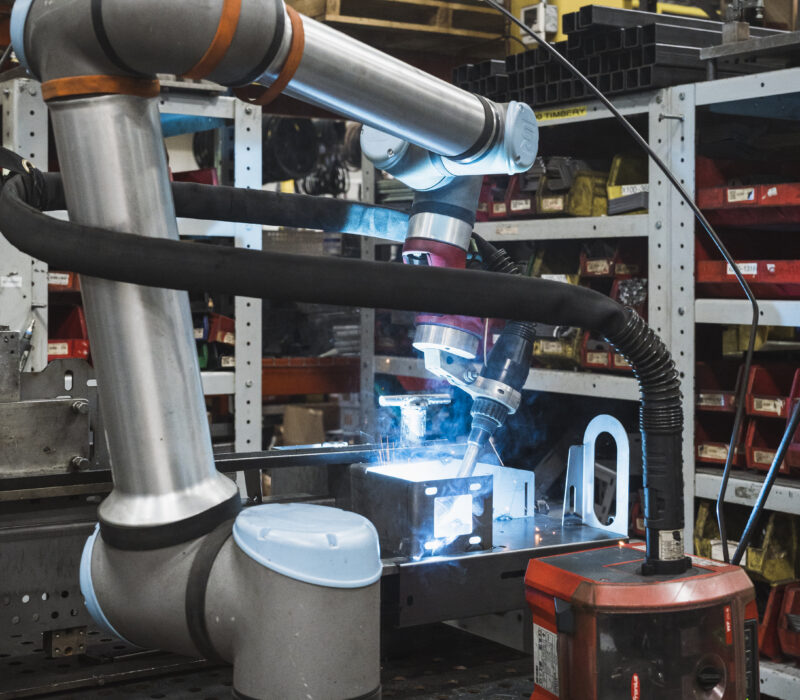

When Darryl received a marketing email from Indianapolis-based THG Automation, he discovered that the company was combining Universal Robots collaborative robots (cobots) with proprietary welding software and Fronius welding equipment to automate applications/functions that are low-volume and high mix in nature. “I had never heard of THG Automation or this type of technology,” Darryl said, but he and Jeff Edwards, the manufacturing director who is a welder by trade, began researching the idea: “Maybe we can implement this technology in our Indiana facility,” we said.

They met with THG Automation and learned quickly that the company had done considerable testing and developed an easy-to-use system. “That is really what sold us on it,” Darryl said. “While it’s a sophisticated system, the software and controls are easy-to-use and intuitive. We were impressed enough that we decided to purchase 10 of them by the end of 2021 and started by purchasing six.” Wood-Mizer was one of the first customers to purchase a THG Automation collaborative welding system, and when Darryl learned about the Manufacturing Readiness Grants program, his plan to incorporate all 10 of the cobot welding systems slid into place. “With traditional robots, we often had to build brand-new fixtures and take a lot of time adjusting the programming,” he explained. “We’re low volume by comparison with the automotive industry. We pretty much build what we need in the next two weeks. And these cobot welding systems are ideal for that.”

Manufacturing Readiness Grants provided by the Indiana Economic Development Corporation and administered by Conexus Indiana are available to Indiana manufacturers willing to make capital investments to integrate smart technologies and processes that improve capacity and productivity. Wood-Mizer invested in several collaborative welding systems with the help of a Manufacturing Readiness Grant.

Key Learnings

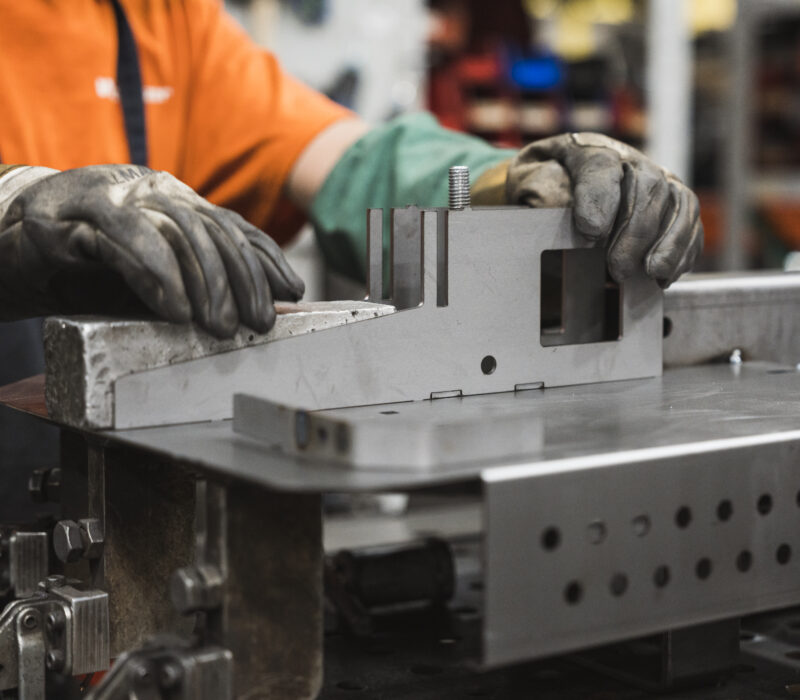

Automation and human labor are optimized in the Wood-Mizer factory: welders work side by side with the cobots.

Equally important to Wood-Mizer’s founders’ vision for how a company should operate, the new technology doesn’t take the welder out of the equation. “Obviously we want to increase productivity and speed,” Darryl said, “but quality is a big piece for us and it’s becoming more difficult to find experienced welders. At Wood-Mizer, an employee is assigned to each welding system, and the production becomes a true collaboration between the worker and cobot. “There might be an area the cobot can’t reach or a particular place that is critical for quality, so you might see a worker make a few welds of their own in those places. It’s a collaboration.”

“Our welders are proud of their work with the cobots. They want to weld, and with this technology, they do,” Darryl said. While deploying 10 of these systems in just one year has been a rapid uptake for Wood-Mizer, the workforce continues to benefit from these investments. “The new collaborative systems are not like our larger robotic welding systems, where employees just load fixtures for the robot to weld. Our workforce is now more involved in the more complex welds, and the more repetitive and monotonous tasks are automated,” Darryl added.

Build trusted partnerships with local technology providers to accelerate project success.

When Darryl discovered THG Automation was an Indiana company and one of the few working to develop a collaborative welding system, he liked the idea of developing a strategic partnership. “There were a few companies developing these types of systems, but there didn’t seem to be a market leader,” Darryl said. “We decided we were going to try one, and the Indiana-based technology provider seemed to offer us the opportunity to help them get started, too.” During an onsite visit from THG, Jeff programmed one of our parts in 20 minutes,” Darryl said. “We realized we wouldn’t have to become experts in programming.” He also added that one of Wood-Mizer’s young employees learned quickly how to program the cobot welding system and was very successful. “Our Batesville manufacturing facility went from 10% tech-enabled to 50% or 60% quickly. And the adoption of cobots have been a big part of that.”

He stressed that having statewide incentives to encourage investments in technology will help Indiana factories compete globally. “I think Indiana is a great state,” Darryl said. “We can compete with Germany, China, Japan and anywhere else in the world. And it’s not the big companies we should be worried about; it’s the small- to mid-sized companies that need to be looking at these technology adoption programs to keep advancing their competitive edge.”

“Our Batesville manufacturing facility went from 10% tech-enabled to 50% or 60% very quickly. And the adoption of cobots have been a big part of that.”

Darryl Floyd

North America President at Wood-Mizer