Photon Automation Develops and Deploys a Proprietary Fiber Laser Welding System for Assembly of High Energy-density Batteries Used in Next-generation Transportation, Telecommunications and Consumer Products

Photon Automation Inc.

Case Study

Key Stats

Company History

Founded in 2000, Photon Automation has earned a global reputation and Fortune 100 customers for its expertise in laser applications and automation solutions.

Photon Automation is another uniquely Hoosier story of a partnership started in a garage that has grown in less than 25 years into a company with a global footprint, counting some of the most prestigious brands in its customer base. Of the original three founding partners, two remain with the company today—William (Bill) Huffman as CEO and partner Richard Mudd (the third, Jason Webster retired in 2022)—along with Photon Automation’s 67-person workforce. The three co-founders started Photon Automation “literally on the last day before our previous employer shut business down,” Bill recalled. “That company fell on some hard times financially. And rather than go get new jobs elsewhere, we decided to start our own company.

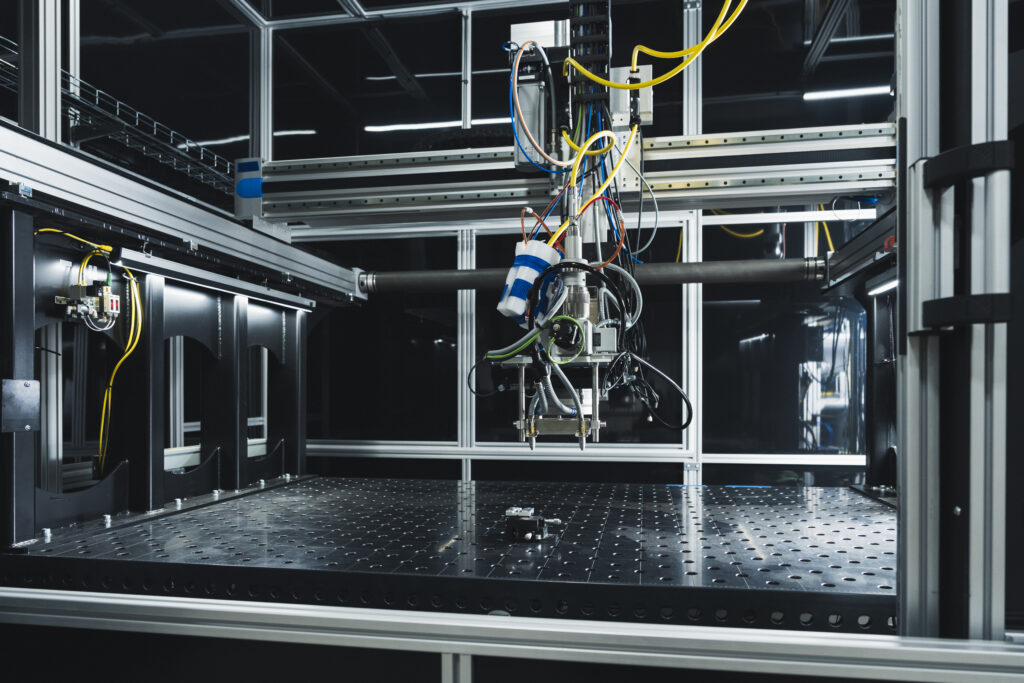

“All three of us are technical people, each with a separate area of expertise. Jason was a wizard at digital engineering and design. Rick is a Purdue electrical engineering graduate and a control programming guru, who’s able to build things. And I brought domain enterprise in laser applications to the table. I’ve been working with laser systems since the 1980s.” Today, Bill continued, most of Photon’s automated systems interact with a laser, typically a high-powered fiber laser. “We combine that with robotics and vision systems with intelligent controls, to produce a total solution for the production of next-gen batteries and other products.” Photon Automation is known for creating automated systems that include state-of-the-art laser technology with the integration of visual inspection/machine vision and advanced robotics. Bill said, “A sophisticated laser system is a must-have in the world of manufacturing batteries and electric vehicles (EVs). We continue to build capacity to assemble and test high-capacity batteries for these industries of the future here in Indiana.”

The Project

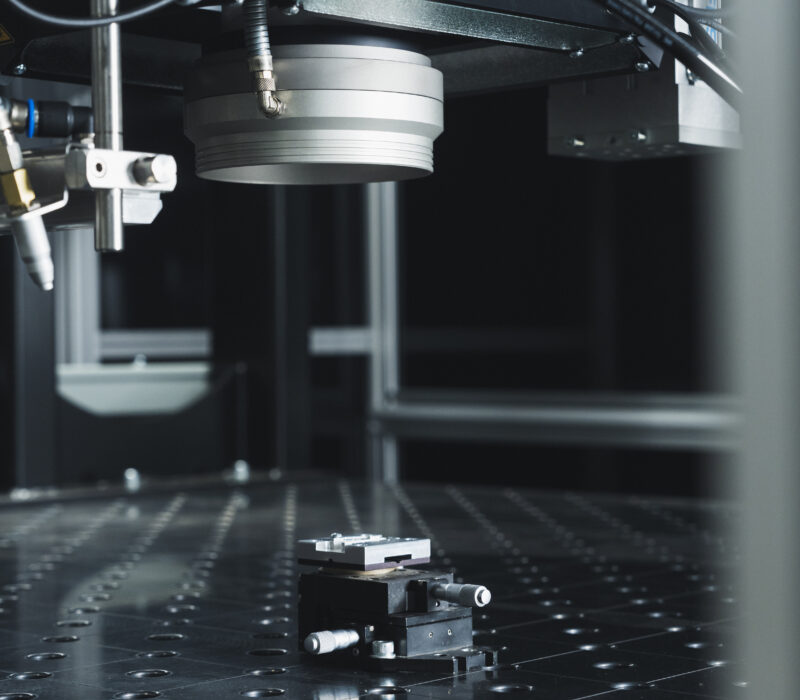

Photon Automation’s automated laser welding system provides flexibility for both assembly of different battery sizes and materials as well as for low-volume contract manufacturing.

Originally, Photon’s project was designed to help develop new battery products. But when it expanded in scope with the addition of low-volume contract manufacturing capabilities, it caught the attention of the Manufacturing Readiness Grants program. The technology project grew in complexity to include not only the tools for producing a part, but new equipment and machines for use in low-volume contract manufacturing of Photon’s customers’ prototypes and products. The project goes far beyond industry standards for battery manufacturing by integrating robotics, software, machine vision and proprietary algorithms to precisely control the weld profile. Another benefit directly addressed economies of the future, such as energy storage and sustainability, especially important in the medical device and EV markets.

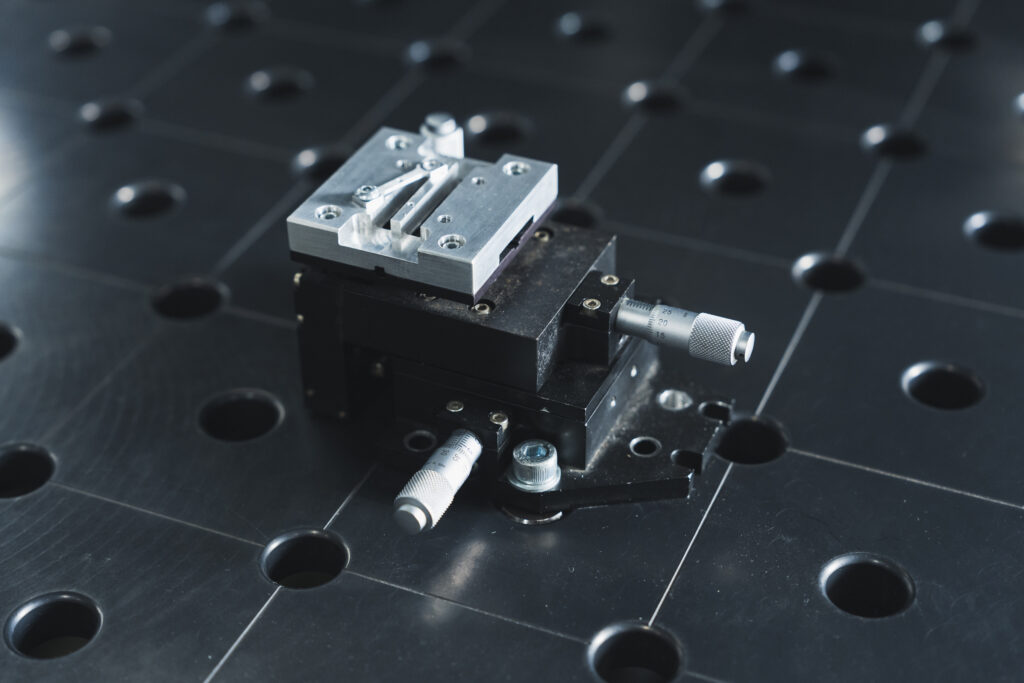

Envisioning and then creating an innovative use of state-of-the-art laser welding technology required assembling what Bill called “a cross-functional team.” Engineers, laser experts and project managers were among those chosen for the project. The resulting design incorporated flexibility to address the many different sizes of batteries and materials necessary for the manufacturing and assembly processes and for expanding the project scope to handle many different applications. The solution was to use different laser heads for batteries suitable for transportation, telecommunications and consumer products. Advanced lasers were the key to much of the project development, and Photon Automation was one of the few Midwestern companies with deep domain-space expertise in laser applications to make it a successful project.

“If you walk through our plant today,” Bill said, “you can see applications being tested on different products everywhere. We did a laser weld for a robotic surgical tool that required very precise welding. We have done work for high-end transducers with rare materials. These are applications so tiny that you can fit several of the products in the palm of your hand. Whether it’s advanced sensors, medical devices, electrification with batteries or energy storage, we are supporting the economies of the future. We’re pushing the envelope of innovation in manufacturing for our customers.

“The battery in an electric vehicle may look like batteries you would put in your flashlight. But they’re not. They are lithium ion-based and if you don’t have precise control of the laser power, you run the risk of penetrating the battery and creating a leak that will result in an issue down the road.” The automated laser welding system was designed to modulate the laser power rapidly and on demand, unlike many other competitors in the industry.

Manufacturing Readiness Grants (MRG) provided by the Indiana Economic Development Corporation and administered by Conexus Indiana are available to Indiana manufacturers willing to make capital investments to integrate smart technologies and processes that improve capacity and productivity. A $183,000 Manufacturing Readiness Grant helped Photon Automation design and build an automated fiber laser welding system to assemble high energy-density batteries for its transportation, telecommunications and consumer products customers.

Key Learnings

Photon Automation built its training program in-house due to the unique and custom nature of its automated laser welding system.

The company added two new employees to the laser application team, one of them specifically hired to run the system. “They both know the system and have learned how to use it,” Bill said. “Clearly an engineering background or degree is preferred for the job, but our team had to learn many more aspects to implement the project effectively. Bill continued, “the applications we’re doing at Photon are not something you can just look up on the internet and get a solution to. They’re truly one-of-a-kind.” At a minimum, he explained, operators must learn how the devices run and how the lasers are controlled.

“For example, when we’re pursuing a contract manufacturing project, our applications engineering team and physicists work on setting up the equipment,” Bill said. “Our mechanical engineering staff designs the parts-specific tooling, and then those two groups work together to execute the production run.”

Workforce expertise and careful project planning ultimately drive the successful deployment of new technology and processes.

“To tackle the implementation of the project, we leaned heavily on the people in our workforce who know the technology,” Bill advised, “and that means the staff that understands the nature of our business. In our case, these are our people in-house with years of experience in the industry and in the design realm. They already know what components work well with what other components.” Furthermore, Bill advised on planning for additional time to iterate, because it’s unlikely the newly designed system will work ‘right out of the gate.’”

Perhaps most important, Bill warned other companies to exercise caution about moving too rapidly with the deployment of new technology and processes. “Realize that automation rarely works when you first flip the switch on. Count on a substantial amount of debugging and development time. Don’t short yourself on those.”

“A sophisticated laser welding system is a must-have in the world of manufacturing batteries and electric vehicles (EVs). We continue to build capacity to assemble and test high-capacity batteries for these industries of the future here in Indiana.”

Bill Huffman

Co-founder & CEO at Photon Automation Inc.