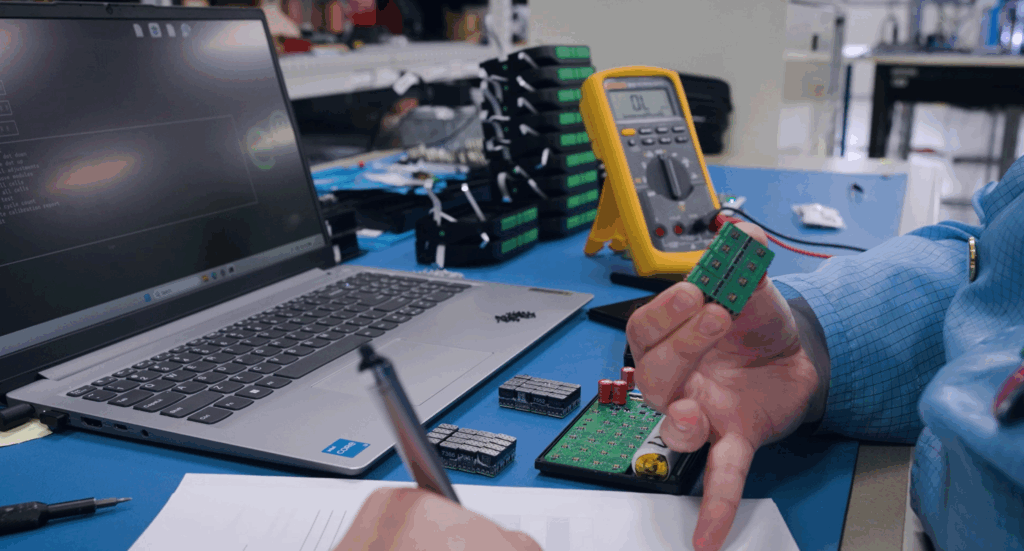

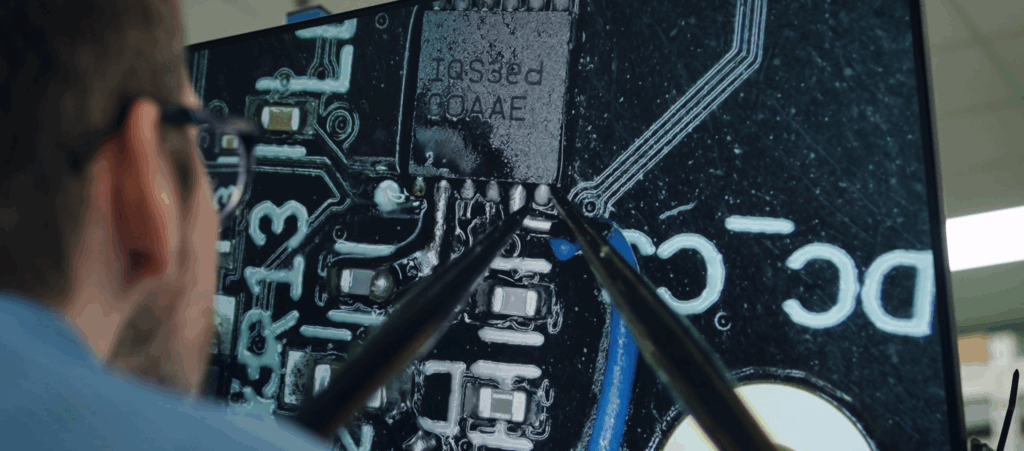

Tactile Engineering Design Engineer Nick Will and CEO Dave Schleppenbach show various parts and machines at the Cadence tablet factory. Schleppenbach gives a tour of the facility.

The Cadence tablet has several buttons and a screen of plastic dots that rapidly pop up and down. An iPhone shows graphics and controls which are represented on the Cadence tablet. Guests in bleacher seats at the Indianapolis 500 race use laptop Cadence tablets, which display animated graphics of the racetrack and moving cars. Four Cadence tablets are connected, forming a larger screen.

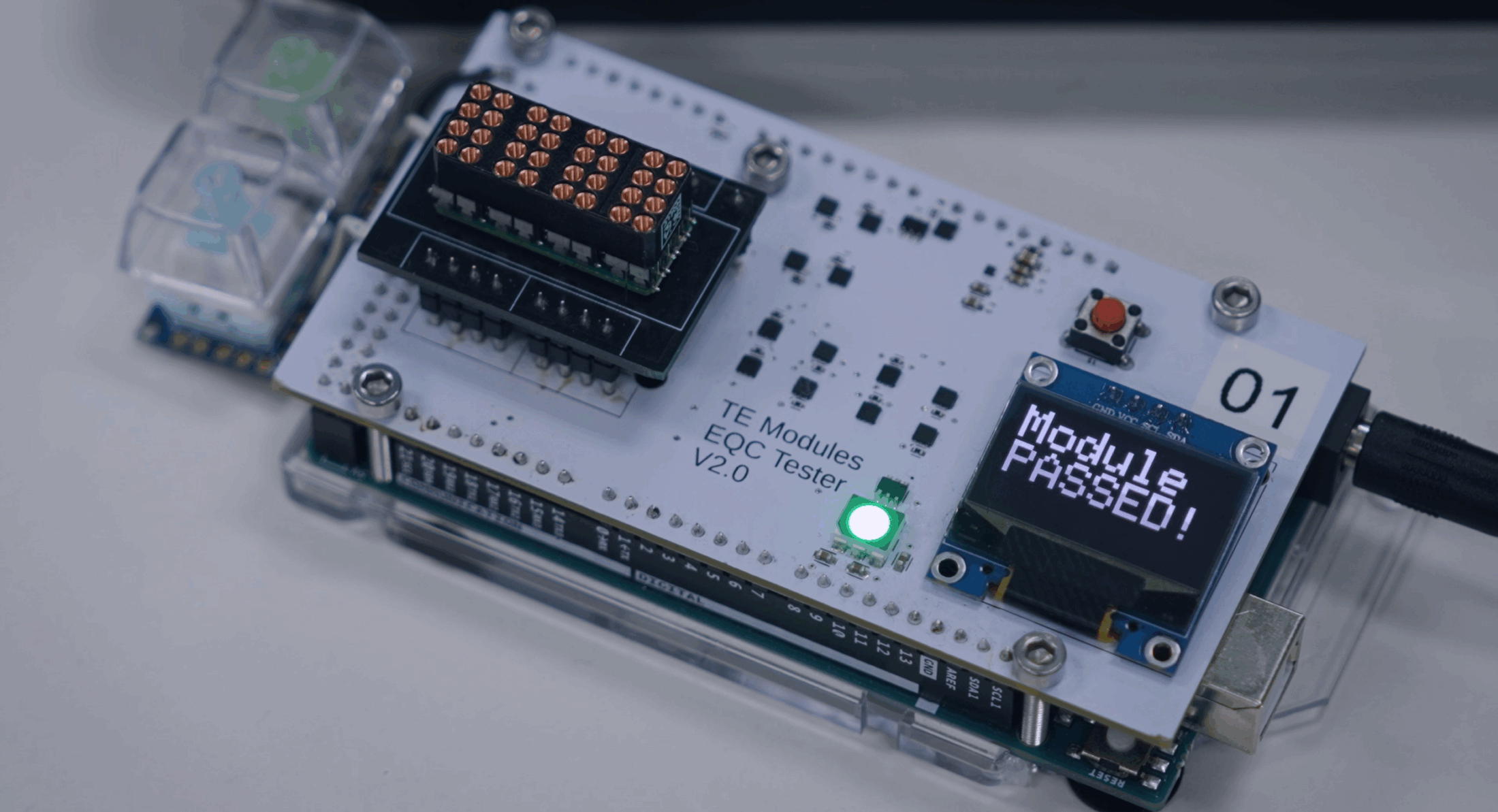

Founded by three Indiana entrepreneurs in 2013, Tactile Engineering’s mission is rooted in breaking down communication barriers for blind and visually impaired individuals. After years of conceptualizing and prototyping, Tactile developed the Cadence Tablet – the world’s first mass-produced, portable tactile device with a 24-by-16 grid of actuated dots. The tablet’s hardware actuates these dots to generate multi-line Braille text, video games, or even real-time graphics that allow users to more fully participate in events – like the Indy 500.

Scaling the production of the Cadence Tablet requires a special type of resourcefulness – especially for the precise installation of those tiny braille dots. Rising 30 Honoree Nick Will, who joined Tactile as a Purdue University senior, championed the solution to this challenging production bottleneck by inventing the “Dot Bot” – a 3D printer that has been given new life as a high-efficiency dot placing tool, using a vacuum pump, vibrating bowl feeder and custom Python software scripts to precisely install all 384 dots in every production Cadence Tablet. This solution replaced a tedious manual process while allowing Tactile to continuously meet product demand, shorten production times, and reassign human efforts to more analytical and enjoyable tasks. As demand continues to increase, the Cadence Tablet’s introduction represents a breakthrough in accessibility technology and the beginnings of a worldwide tactile communication network for the blind and visually impaired.